Innovative Technologies, Common Challenges, and Interesting Conversations: Pepperl+Fuchs at Hannover Messe 2024

With the motto “Energizing a Sustainable Industry”, this year's Hannover Messe was all about sustainability. More than 4,000 exhibitors presented their latest products and solutions relating to digitalization and automation, artificial intelligence, and renewable energies to over 130,000 visitors from 22 to 26 April. All of them are intended to help make industry more sustainable in the future. Dr. Gunther Kegel, CEO of the Pepperl+Fuchs Group and President of the German Electrical and Digital Manufacturers' Association (ZVEI e.V.), is optimistic in this regard after the last few days of the fair: “We can confidently take on major social challenges such as curbing global warming if we take the right measures and consistently pursue the path towards electrification, digitalization, and automation. Companies in the electrical and digital industry have impressively demonstrated how innovations, in particular the use of artificial intelligence, open up new options for action—for more climate protection and greater efficiency in energy consumption and resource use.”

Prominent Visitors from Politics

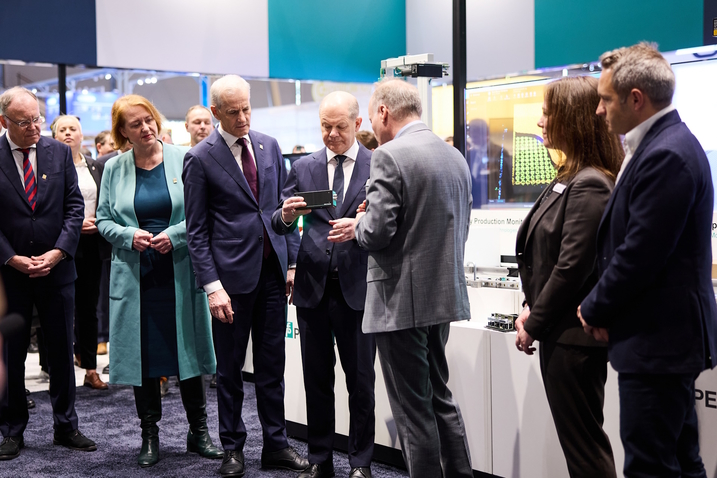

This year in Hanover, Pepperl+Fuchs not only presented its latest innovations and highlights from the fields of sensor technology and explosion protection, but also welcomed several visitors from politics to its booth. On the first day of the fair, German Chancellor Olaf Scholz, together with Jonas Gahr Støre, Prime Minister of this year's partner country Norway, and other members of the German Bundestag, took a look at innovative automation technology as an essential basis for digitalization and electrification in industry. At the booth, Kegel demonstrated to the political representatives what modern, automated battery cell production can look like, the role of the SmartRunner Explorer 3-D vision sensor from Pepperl+Fuchs, and the advantages of using artificial intelligence.

Dr. Gunther Kegel, together with shareholders Monika Müller-Michael and Michael Fuchs, welcomed Chancellor Scholz and Norway's Prime Minister Støre to the Pepperl+Fuchs booth

Constructive Conversations: Global Challenges and Innovation in Germany as an Industrial Location

During his visit to the fair, Vice Chancellor and Federal Minister for Economic Affairs and Climate Protection Robert Habeck also spoke with CEO Kegel at the booth about the global challenges of climate change. Kegel emphasized the importance of automation and digitalization for achieving greater energy efficiency and highlighted the important contribution of Pepperl+Fuchs to a more sustainable industry. On the one hand, the company offers automation components that are essential for the transition to climate-friendly production and the development of an “all-electric society”. At the same time, the products and solutions play an important role in safe automated processes along the entire value chain of green hydrogen—from energy generation to use in industry and transportation.

Robert Habeck and Dr. Gunther Kegel at the Pepperl+Fuchs booth

Baden-Württemberg's Minister President Winfried Kretschmann and Environment and Energy Minister Thekla Walker also convinced themselves of innovative automation technology as a cornerstone for greater sustainability. The southern German state is home to numerous global players and hidden champions in the industry. During his tour of the fair, Kretschmann focused in particular on the future topics of Industry 4.0 and artificial intelligence. The visit to the Mannheim-based automation specialist Pepperl+Fuchs was therefore more than obvious. Lutz Liebers, Reiner Müller and Florian Ochs, members of the Pepperl+Fuchs Management Board, welcomed the delegation around Kretschmann and demonstrated the highlights at the trade fair booth.

Partner Country Norway—the Powerhouse in the North

There could hardly have been a more fitting partner country for the overarching theme of this year's Hannover Messe than Norway. The country in Europe's far north rightly presented itself at the industry meeting point under the motto “Pioneering the Green Industrial Transition”—after all, it is a pioneer in the use of new technologies for more climate protection. In 2023, for example, zero-emission vehicles accounted for more than 80 percent of new registrations in Norway. Hydroelectric and wind power plants have not only become important energy suppliers in the country, but also make energy from renewable sources an important export commodity. With a site in Porsgrunn, Pepperl+Fuchs also supplies Norway with crucial components and solutions for automation, digitalization, and electrification in order to jointly meet the challenges of climate change. Learn more about our activities in Norway.

Positive Summary

While Hannover Messe 2024 remained at the previous year's level in terms of numbers, the Pepperl+Fuchs Group was able to record an increase in visitors to its booth. Looking back, Stefan Maus, Senior Vice President Global Marketing at Pepperl+Fuchs, is extremely satisfied. “Our booth was very popular with our visitors this year and received a consistently positive response. I am very pleased that we were once again able to present our expertise in the areas of high-performance sensor technology and explosion protection with our mix of digital exhibits and real products.”

It's all in the mix: Digital exhibits and hands-on products complemented each other at the Pepperl+Fuchs booth

Our Fair Highlights

Didn't manage to visit our booth in person this year and talk to our experts? Take a look at past highlights—and make a note of the date for the next Hannover Messe. Our experts look forward to your visit from March 31 to April 4, 2025 and to talking to you in person. The partner country will then be Canada.

Industrial radar sensors are particularly resistant to interference and withstand virtually all environmental conditions. Learn more about their functional principle and how they can be used effectively in various applications.

The distance sensors of the R200 series integrate powerful Pulse Ranging Technology (PRT) in a compact standard housing—for precise measurement results at distances of up to 60 m. Discover the new sensor series at our trade fair booth.

The advantages of our proven absolute linear positioning systems safePXV and WCS are now combined with a safe evaluation unit. Find out more about the positioning systems that enable safe position and speed detection up to SIL 3 and PL e in one system.

Ethernet-APL is the key technology that brings Ethernet to the field of process plants—paving the way for IIoT applications. Learn all about the history, definitions, standards, and topologies of this groundbreaking technology.

The new 8" and 10" Windows tablets are ideal for use in intralogistics, manufacturing, and the automotive industry. Discover the features of the Tab-IND series and the possibilities offered by the smart back technology.

The new HiC2422 interface module has two freely configurable channels, which means it can be used both as a SMART transmitter power supply and as a current driver for valve positioners. Find out how this dual functionality ensures cost savings.

The "Manufacturing-X" initiative intends to create a sovereign data space across industries and companies to take multilateral collaboration and digital value creation processes to a new level. Get an insight into the intelligent use of various technologies and standards for end-to-end digital collaboration within such a data ecosystem.

Duration of the event: 5 days

Number of visitors: 130,000 visitors from 150 nations

Number of stands: 4,000 exhibitors

Number of start-ups: 300

Partner country: Norway

+61 3 9358 3400

+61 3 9358 3400