Delivering intelligence.

Discovering solutions.

Unlocking all frequencies.

RFID from Pepperl+Fuchs

Features

Service and Support from the RFID Experts

Tailor-Made Identification Solutions

High Compatibility for Easy Integration

NEW! Our Latest Portfolio Additions

A new RFID gate reader solution from Pepperl+Fuchs creates seamless transparency when detecting large quantities of RFID tags. The cost-effective system is based on powerful, standardized UHF RFID technology (ISO 18000-63 and EPC Class 1 Gen 2) and is specially optimized for use in logistics applications, such as tracking incoming and outgoing goods.

Learn more

An incomparably high read range and a wide variety of helpful additional features housed in a space-saving, optimized flat-pack design: With a new series of RFID read/write devices, Pepperl+Fuchs now offers this attractive complete package as a solution for identification tasks.

Learn more

Pepperl+Fuchs expands its portfolio of UHF read/write devices with the new F191: It combines the advantages of industrial UHF technology with a standardized interface for IO-Link communication—and is therefore a cost-effective enabler component for a wide range of standard applications in areas such as intralogistics, automotive, and material handling.

Learn more

Using a sophisticated mechanism, RFID read/write heads for different frequencies (LF, HF, UHF) can be quickly and easily attached to the handheld's base module without any tools. This ensures users can concentrate completely on the identification task at hand. To help with this, the basic device has a 4.8-inch capacitive, hardened color touch display, which can be read clearly at all times even in suboptimal ambient light conditions. IP54 protection emphasizes the device's suitability for use outdoors and in other challenging environments.

Learn more

The F190-B40 UHF RFID read/write device offers an integrated industrial Ethernet interface and REST API. Using these interface technologies, this read/write device, which is designed for medium detection ranges, can be quickly and easily integrated into OT and IT systems, making it an attractive solution for production control and monitoring, track-and-trace applications, and other Industry 4.0 applications in factory automation.

Learn moreProducts

Applications

In the field of RFID technology, Pepperl+Fuchs offers a complete portfolio of perfectly matched components that solve a wide range of identification tasks. Find out more about possible areas of application.

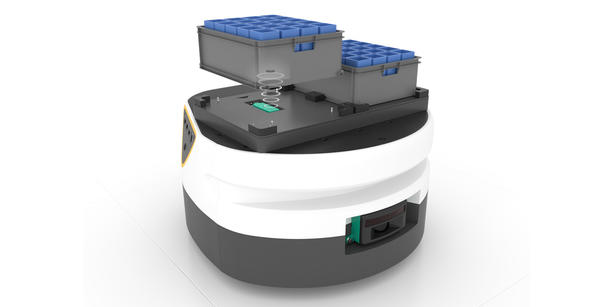

RFID Meets AGV—Three Examples of Practical Applications

Whether as practical automated guided carts, rolling assembly platforms, or massive self-driving container tank transporters, automated guided vehicles (AGVs) in all possible designs have become indispensable elements in modern production processes. They help to make everyday work significantly easier, preserve existing resources, and speed up transport processes considerably. They differ widely in appearance, and the technologies that enable the vehicles to work automatically or autonomously are highly diverse.

RFID is often used, and when applied intelligently, this radio-based identification method can perform numerous tasks on the AGV. This blog article presents three possible versions.

RFID in Hazardous Areas—Three Examples from the Field

The range of RFID applications is by no means limited to discrete manufacturing—it is also becoming increasingly popular in process plants due to the ever more extensive requirements for marking product and work equipment. However, explosion protection requirements often have to be taken into account, because wherever flammable gases, vapors or dusts are generated, electrical equipment poses a significant safety risk.

In this blog article, you will gain insight into three application examples that will help you understand the successful and safe use of RFID in hazardous areas.

More Application Examples for RFID

RFID is an extremely versatile technology that is applied in many sectors. We compiled ten more application examples from ten industries for you. Get inspired by the use cases and learn how flexible RFID technology boosts reliable identification and overall efficiency under a variety of circumstances …

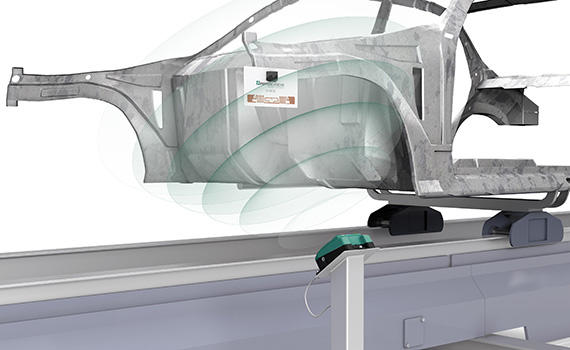

RFID Fuels Industry 4.0

RFID is a key enabler for future-proof digital factories in the sense of Industry 4.0: when a product is marked with an RFID tag it stores information about necessary production steps or special requirements. More than that, it can store new, additional information when the production steps have been completed. Attaching RFID tags to production items introduces dynamic structures and flexibility to all areas of manufacturing. Get additional information on technology for Industry 4.0 by Pepperl+Fuchs—labeled as "Sensorik4.0®".

RFID Solutions

In a research project at the Karlsruhe Institute of Technology (KIT), twelve partners from industry and science joined forces to develop a flexible transport system. The result is KARIS PRO, an autonomous vehicle that is currently tested in practice. Dieter Schneider, Team Leader R&D Identification Systems at Pepperl+Fuchs, gives insight into the project...

RFID Product Manager Dr. Klaus Schmitt takes you on a tour and provides insights into our solutions specifically tailored for meat processing industries.

Reading recommendation: 5 Reasons to Use Industrial RFID in Your Meat Processing Plant

Frequently Asked Questions on RFID

Part 1: General Questions on RFID

Are you interested in RFID technology but are not sure where to start? The first part of our FAQs gives you an overall insight into RFID. Learn about the basic components that constitute a setup, the history of the technology, and the major benefits that RFID can bring to identification tasks in your particular process …

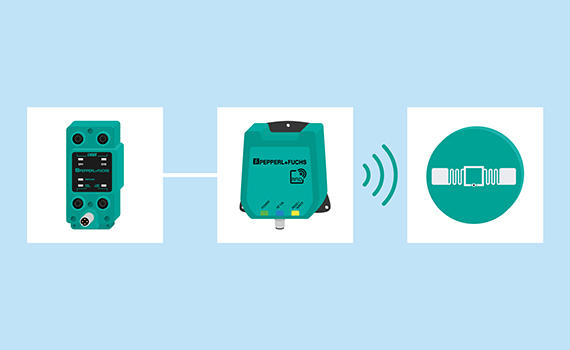

Part 2: RFID Read/Write Devices

Reliable non-contact identification depends on high-quality read and write devices. Get to know the functional principles of RFID read/write devices. How do they work and which types are available on the market? Which role does antenna polarization play and how do you avoid crosstalk? Also, get advice on how to choose the RFID read/write device best suited for your application …

Part 4: RFID Tags

RFID tags are diverse products and can be found in industrial applications as well as in our private lives. Learn about the functional principles and different tag types. When should I use an active instead of a passive tag? How much information can one tag store? How do tags fare in terms of durability when your application is rather challenging? …

Part 3: RFID Frequencies

To enable noncontact data exchange via an RFID system, radio waves are used for communication. Depending on the application requirements, RFID systems utilize different frequency ranges. Gather insights into the characteristics of these ranges. What defines them? Where are they being used? What can affect the signal transmission? …

Downloads

Downloads More Information

More Information

+45 7010 4210

+45 7010 4210