Designed for Flexibility

As the inventor of the proximity sensor and a pioneer in sensor technology, Pepperl+Fuchs is continuously developing new products and technologies that can be seamlessly integrated into your unique application. Active Shielding Technology was developed to get the most out of mechanical tolerances and achieve consistently high switching distances.

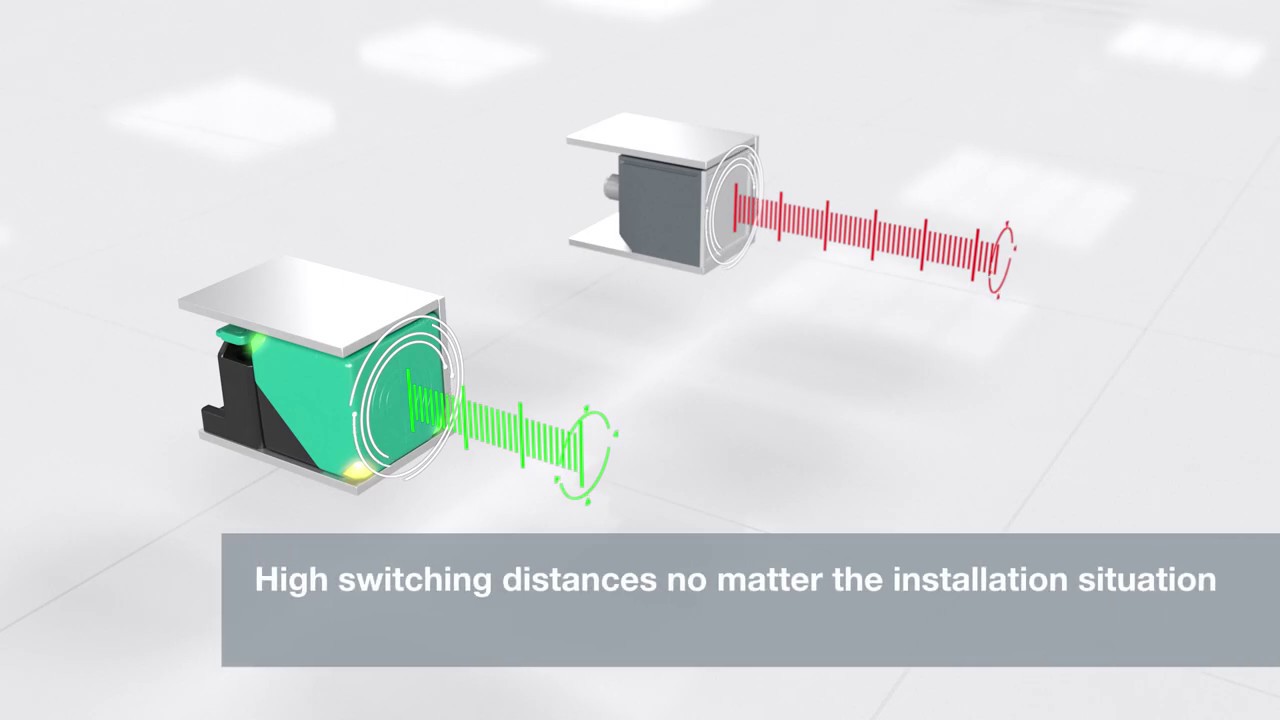

Now integrated into the VariKont series for the first time, the technology gives sensors the ability to actively detect both the target and the installation environment, keeping the switching distances high, no matter the installation situation and the surrounding material. Benefit from easier equipment design and reduced costs!

Highlights

Consistently high switching distances of 30 mm for flush mounting and 50 mm for non-flush mounting—regardless of the installation situation!

Flexible system planning and easier equipment design

Adjustable sensor head for quick and easy installation

Convenient status monitoring via high visibility corner LEDs

Internal quality testing goes above and beyond the requirements of target industry machine applications

Benefits

Reliable Technology

No matter the installation situation, VariKont sensors with Active Shielding Technology achieve high switching distances of 30 mm flush and 50 mm non-flush. The high-EMC sensors are insensitive to external influences and mechanical loads, and can operate in temperatures ranging from -25 °C to +70 °C.

Flexible Application Design

Offering the maximum installation flexibility with no effect on the switching distances, active shielding technology simplifies equipment design and reduces costs.

Simplified Status Monitoring

High visibility corner LEDs enable status checks at any time and from any perspective.

Fast Installation and Easy Device Replacement

Both versions of the sensor feature an adjustable sensor head and offer user-friendly installation and replacement. The sensor head can be rotated in five directions for optimal alignment with the target.

More Flexibility in Application Design

Mounting materials and installation conditions influence the switching distance of inductive sensors, especially those with long detection ranges. This influence must be kept as low as possible so the sensors can be used at the highest possible switching distance. Conventional sensors use shielding measures to achieve this, but they often result in losses and limit ranges.

With the help of the newly developed Active Shielding Technology, challenging installation situations and high switching distances can be achieved simultaneously. The -25 °C to +70 °C temperature range also remains stable compared to that of competing sensors with increased switching distances.

Secondary Coil Compensates for Environmental Influences

The VariKont and VariKont L2 inductive sensors with high switching distances operate with a primary and secondary coil. As with conventional sensors, the primary coil detects the target. At the same time, the secondary coil measures the environment, including the installation situation and the surrounding material.

The information obtained is then used to compensate for environmental influences. This helps achieve high switching distances of 30 mm flush and 50 mm non-flush.

Contact Us

Have any questions about the VariKont Series with Active Shielding Technology, or want to receive more information? We are happy to help! Simply fill out the contact form and send us a message.