Precise Absolute Position Detection: IO-Link Interface for the WCS Position Encoding System

Pepperl+Fuchs now offers a variant of the WCS position encoding system with IO-Link interface.

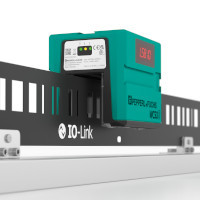

The tried-and-tested WCS position encoder system stands for absolute position detection with millimeter precision and is used in conveyor systems, among other applications. Due to its robust design, it is also suitable for outdoor use or harsh environmental conditions. Since its market launch in 1989, the WCS has been continuously developed and optimized. Pepperl+Fuchs is now adding a variant with an IO-Link interface to its existing portfolio of absolute positioning systems. This allows it to be integrated into IIoT applications quickly, easily, and cost-effectively. In addition, the new variant ensures predictive maintenance through comprehensive data sets.

Efficient Solution for IIoT Applications

The new system variant with the series designation WCS3B-LS810 has identical dimensions to the previous devices. This means that existing code rails, mechanics, and accessories such as outdoor housings and carriages can continue to be used without restriction. This makes the switch to the new version especially cost-effective for existing installations. Users of the WCS with IO-Link interface also benefit from the advantages of the future-oriented communication technology, which makes commissioning and data integration particularly easy, for example. As the WCS3B-LS810 is compatible with a wide range of IO-Link devices, it can be used to implement a cost-effective system solution—especially if the system is already equipped with a corresponding IO-Link structure. A universal fieldbus connection is easily possible with an IO-Link master, for example from the ICE2 series.

Comprehensive Data Sets for Predictive Maintenance

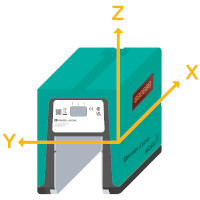

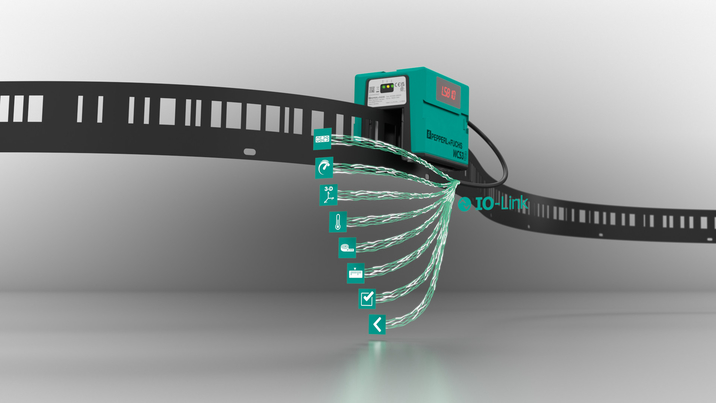

Additional sensors for acceleration and temperature measurement are integrated into the read head of the absolute positioning system with IO-Link. In addition to position and speed data, the sensor provides additional information for continuous monitoring of the customer's system, such as temperature, acceleration values in three axes, and a direction bit. The new version also offers a “heartbeat signal”, which indicates the active operation of the read head even when a position is held for a longer period of time. This data enables comprehensive monitoring of the sensor and its environment, therefore simplifying predictive maintenance.

Optimum Adaption to the Individual Application

With the additional data from the integrated acceleration sensor, the WCS read head can be installed particularly flexibly. The display rotates automatically so that the displayed value can be easily read in any mounting position. The WCS with IO-Link can also be combined with three options from the existing portfolio: The IO-Link interface is available for the standard version, the display option, and the version specially designed for outdoor use with outdoor housing and heating. The latter can withstand extreme temperatures down to -40 °C.

The additional switching output of the read head can also be configured to identify up to five individual position ranges, therefore replacing limit switches. With a dynamically adjustable preset value, the WCS with IO-Link outputs the absolute position in relation to a preset value instead of the actual position. The sensor can also be used to identify individual moving components: Up to 1,260 code tape sections are reliably recognized as ID numbers.

The advantages of IO-Link in combination with the proven positioning system make the WCS with IO-Link interface an ideal solution for precise absolute positioning in IIoT applications.

Highlights

- Absolute positioning with millimeter accuracy over 314.5 m—including in harsh environments

- Economic solution: IO-Link for simple commissioning and seamless integration into IIoT applications

- Optimum plant availability: integrated acceleration and temperature sensors enable predictive maintenance

- Reliable processes through output of position ranges, heartbeat signal, and direction bit

- High flexibility: automatic display rotation, preset function, and muting control for optimum adaptation to the application

+33 1 60921300

+33 1 60921300