Unlimited Solutions.

Particularly robust and reliable automation technology—even in harsh environments.

Sensors, Systems, and Solutions for Mining and Metals

Whether in surface or underground mining—the extraction of metals, ores, and minerals forms the basis for economic prosperity and technological progress. The right automation technology helps to make mining processes safer and more efficient. For example, collisions can be avoided, dangerous situations can be recognized at an early stage, and the waste of resources can be prevented.

Pepperl+Fuchs' extensive portfolio includes highly robust and reliable sensors, systems, and solutions that withstand the adverse conditions in mining—from extreme temperature fluctuations to dirt and dust in the air. The products ensure smooth processes in a wide variety of process steps. In every region of the world, our experts are at your side with detailed application analyses and comprehensive technical advice.

Find the optimum solution for your individual mining challenge!

Highlights

Yard Machines

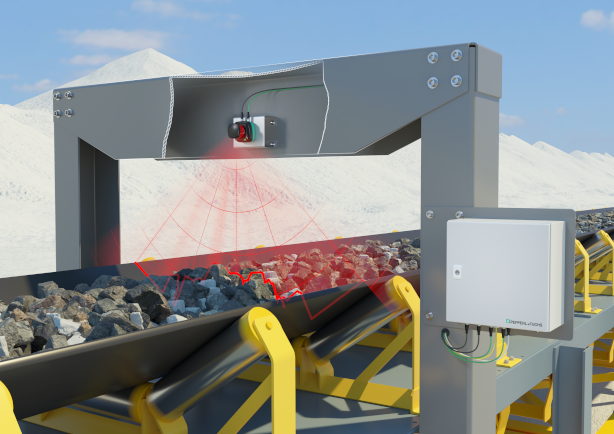

Conveyor Belts

Exact Filling and Traceability

Sprinkler systems in mining are often operated with reservoir trucks that are supplied with water via a filling system. An RFID system offers the ideal solution for adjusting the amount of water to the capacity. At the same time, the traceability of the vehicle can be ensured.

First, the UB*-30GM ultrasonic sensor detects the presence of the water truck. The robust F192 RFID read/write device then identifies the vehicle via a UHF tag, which can be attached directly to the metal tank. The measured values are forwarded to the flow transmitter via the RFID evaluation unit and the controller. This ensures optimum water flow at all times. Furthermore, the UHF tag can store additional information about the vehicle, such as its real-time status or location.

Reservoir Trucks

RFID Solutions

Efficiently Controlling Mining Processes

Modern RFID solutions are increasingly being used for identification tasks in the mining industry. In our blog post, you can find out how processes in mines can be efficiently controlled and monitored with RFID technology.

One of the most important applications of RFID systems in the mining sector is asset management. The RFID tags attached to the equipment enable real-time tracking and data collection, ensuring that each peace of equipment is used efficiently. RFID systems are also critical to improving inventory control. By tagging raw materials, finished products, and even spare parts, mining companies can maintain accurate records of stock levels.

Contact Us

Do you have any questions about our sensors, systems, and solutions for the mining industry? We will be happy to help you! Simply send us a message or make an appointment with one of our experts to get more information on the products you are interested in.

+49 621 776-0

+49 621 776-0