Modular Lightweight.

VisuNet GXP—up to Zone 1/21 Applications

Designed for Zone 1/21 and Zone 2/22: VisuNet GXP

Compact Design

Light Weight

RM Shell

Compact, Modular, and Easy to Maintain

Thin Client Solution with RM Shell

The VisuNet GXP remote monitors are equipped with the latest generation firmware VisuNet RM Shell. It provides easy access and control of process control systems in explosion hazardous areas by using standard Ethernet networking technology. The most recent update supports the latest remote protocol versions, such as RDP 10, VNC, NetC@P, and Citrix.

Secure and Reliable

RM Shell runs on a Microsoft® Windows® 10 IoT Enterprise operating system. The Long-Term Servicing Channel (LTSC) offered with the new Windows version provides long-term availability of security updates, ensuring a safe and secure system at all times. The security functions of the RM Shell, like password-protected access and the definition of user roles, act as additional safeguards.

Innovative Centralized Management

In combination with the innovative software VisuNet Control Center, RM Shell is an efficient solution for a future-oriented remote management of VisuNet remote monitors and thin clients. With the centralized management functions, users are able to remotely configure, maintain, and monitor their remote monitor or thin client installation. A walk back to the plant to configure remote HMI units is no longer necessary for administrators—they can do everything from one central point.

Powerful Computer Unit

With the 2024 generation of the VisuNet GXP, the computing units are now equipped with powerful Intel® Elkhart Lake processors. PC versions of the VisuNet GXP are based on an open Microsoft® Windows® operating system, which offers improved computing power and software flexibility. This allows users to install customized software packages to visualize applications in industrial and hazardous areas.

Various Interfaces

With a variety of available interfaces, the GXP computing unit can be directly connected to a control system or other peripheral devices, reducing the time and money needed for cabling. Whether RS-232, RS-485, or Ethernet, users can choose the appropriate interface for their application. Additional available peripherals help simplify the installation process. The optional fiber optic interfaces, for example, ensure a reliable connection even over longer distances. A great benefit of the fiber optic interface is that it can be connected to standard IT fiber optic switches that are not rated as “optically intrinsically safe” (Ex op is), even from Zone 1/21 areas.

21.5” Display with Full HD Screen

The 21.5” (55 cm) display comes with a Full HD resolution (1920x1080), so it complies to the common widescreen format, guaranteeing compatibility to the aspect ratio and resolution of process images that are designed for modern widescreen operator workstations. Hardened protection glass protects the multi-touch sensor, which allows a touch-optimized user interface, even for use while wearing gloves. The robust and scratch resistant safety glass without any gaps is easily cleaned and perfectly meets the high demands for Zone 1/21 and Zone 2/22.

Compact 19” Display

The newest display unit of the VisuNet GXP family comes in a compact housing and is available as a 19“ (48 cm) version with a 5:4 format. It not only offers a space-saving design, but is also compatible with its predecessor product line, the VisuNet EX1. This means that users can retrofit existing installations easily via a drop in replacement, and are even able to continue using existing keyboards or barcode readers. Just like the larger 21,5" version of the display unit, the 19" model is equipped with a capacitive multi touch sensor which allows touch-optimized user interfaces.

Firmware

Easy Configuration with VisuNet RM Shell

VisuNet RM Shell firmware is pre-installed and pre-configured for various control systems on every VisuNet device from Pepperl+Fuchs. This way, it is quick and easy to get BTCs and remote monitors up and running. The latest generation of RM Shell is based on Microsoft® Windows® 10 Enterprise LTSC 2021, which includes long-term security updates by Microsoft. In addition, RM Shell is equipped with integrated security mechanisms that give the system reliable protection from malware and viruses.

VisuNet RM Shell enables a complete thin client solution for process industries—from BTCs in the control room down to remote monitors in Zone 1/21 and Division 1. And with VisuNet Control Center software, plant operators can configure, monitor, and efficiently manage all devices from one central point.

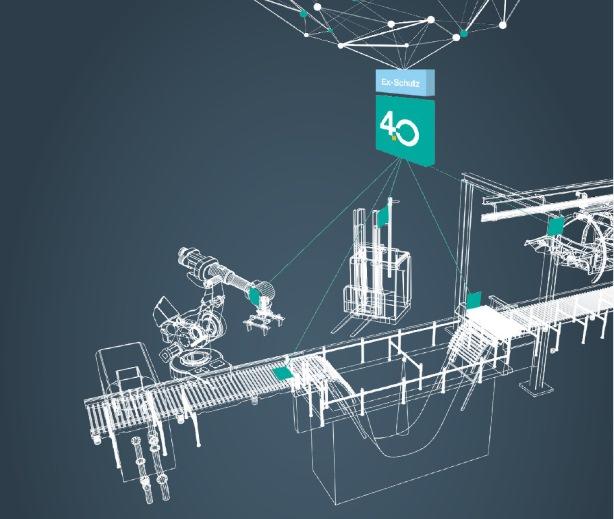

Meeting the Requirements of Industry 4.0

At Pepperl+Fuchs, Industry 4.0 is defined as a complete network of production systems. These systems are characterized by data exchange within the production process, but also with higher-level information systems beyond the company boundaries. This networking of all automation components requires new technologies that enable direct horizontal and vertical access to the information of the production system – all the way down to field devices in explosion-hazardous areas. This means communication along the process chain, in higher-level information systems such as MES or ERP and, at the same time, direct access down to field level.

The new Pepperl+Fuchs VisuNet GXP with the innovative firmware VisuNet RM Shell lets you harness the power of Industry 4.0. For the first time, the smart human-machine interface system enables communication within the production process and direct access to the sensor across all hierarchical levels, including in explosion hazardous areas.

Contact Us

Do you have any questions on the VisuNet GXP, or do you want to receive more information? We are happy to help! Simply fill out the contact form and send us a message.

More Information

More Information

- VisuNet GXP Configurator Configure your own VisuNet GXP

- VisuNet RM Shell Discover the latest generation firmware

- Industrial Monitors and HMI Solutions Take a look at our product portfolio

- From Herbal Medicine to HMI In our amplify story, discover where human machine interfaces and explosion-proof mobile devices from Pepperl+Fuchs are used in Zone 1/21 and Zone 2/22

Downloads

Downloads

- HMI Systems from Pepperl+Fuchs Product portfolio overview (PDF)

- VisuNet GXP Product Information (PDF)

- VisuNet RM Shell 5 for Thin Client Workstations Product Information (PDF)

+91 80 4609 6000

+91 80 4609 6000