Ultrasonic Sensor System USi®-safety in Accordance with Category 3 PL d

Ultrasonic Technology for Safety in All Areas

The USi-safety ultrasonic sensor system is breaking new ground for safety applications—whether in challenging, dusty environments or in outdoor areas. Machines and vehicles can be reliably protected using state-of-the-art ultrasonic technology and all of the advantages this brings.

Intelligent Design for Every Situation

Miniature ultrasonic transducers detached from the control interface allow the USi-safety to be used even in confined installation situations. The special design of the transducers enables the sensor system to cover an elliptical, three-dimensional sound field with opening angles of ± 17° and ± 5°, providing an improved level of safety.

Protected against Manipulation

Preventing safety functions from potentially being manipulated is a recurring challenge when implementing safety applications. USi-safety supports a teach-in process where a machine part is used as a reference target, so that the sensor system can register deviations immediately and the safety function can remain operational.

Quick Parameterization and Automatic Documentation

Comprehensive parameterization software and documentation make commissioning the ultrasonic sensor system quick and simple for users. In addition, the parameterization software can be used to initialize periodic tests and to generate safety protocols for the required safety verification in a fully automated manner.

Technology

Elliptical Sound Field for Especially Wide Sensing Range

Whereas conventional ultrasonic sensors emit acoustic signals in the form of a radially symmetrical sound beam, in the USi-safety this takes the form of a strongly elliptical sound field. The opening angle of ± 17° / ± 5° creates an especially wide sensing range in one plane and a narrow sensing range in the other. This allows the ultrasonic transducers to be mounted in confined installation situations.

The system can therefore be used successfully even just above ground level or close to a wall. At the same time, this technology—which is optimized for capturing 3-D spaces—enables the sensor to detect switching targets or obstacles that are overhanging or near to the ground.

Two Category 3 PL d Safe Systems on a Single Evaluation Unit

Up to two ultrasonic transducers can be connected to the evaluation unit of the USi-safety ultrasonic sensor system. They each have a single-fault tolerance, 2-channel structure. Reliable protection is therefore possible via each of the two independent sensor channels. A safe sensor system is provided even when only one ultrasonic transducer is connected. One signal output and safe OSSD outputs in accordance with category 3 PL d are available for signal output to a safety controller for each connected transducer.

In combination with the detached design of the ultrasonic transducers, which are available with cable lengths of up to three meters, the system can be used very efficiently in applications where left/right or forward/reverse movements in a space need to be safeguarded—on automated guides vehicles (AGV), for example. In addition, applications can also be implemented in which both sound fields are focused directly adjacent to each other or even overlapping to secure the widest possible collective sensing range—for example, as a sound curtain that is used to control access to a work cell.

The Components

The evaluation unit contains two microcontrollers that monitor the connected ultrasonic transducers, their own hardware, and each other to ensure that the components are functioning correctly. This provides the system with single-fault tolerance in accordance with EN ISO 13849-1. In addition to the connections for the ultrasonic transducers and the safe, short-circuit, and crossed-circuit monitored OSSD outputs, there is an input for a temperature sensor and a USB interface for parameterization via PC.

IP69 protection makes the system's two independently operating ultrasonic transducers suitable for even the most demanding ambient conditions. With their miniature design and the detaching from the control interface, they can be flexibly integrated into almost any application even under confined installation conditions. The transducers generate an elliptical sound beam. The system reliably detects even the smallest objects within this wide 3-D sensing range.

To additionally increase process safety, a temperature sensor can be connected to the dedicated input on the control interface as an optional accessory. This sensor provides automatic compensation of temperature-related measurement deviations, such as those that can occur in outdoor applications.

The parameterization software allows a wide range of settings such as switch points, output logic, safety parameters, and ultrasound-specific parameters to be customized. In addition, the user interface can be used to initialize periodic tests and automatically generate safety protocols for the plant documentation.

Application Examples

USi-safety in the Field (Video)

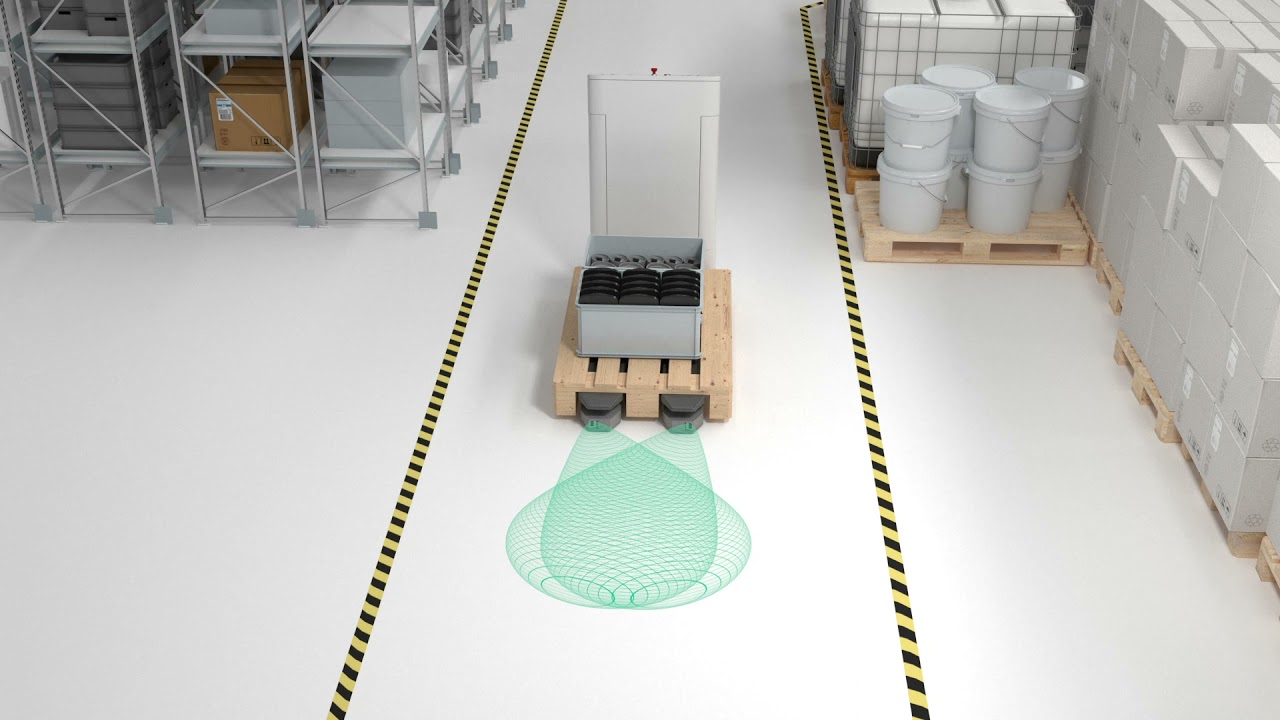

Get an insight into how USi-safety works: our animation shows the system at work and illustrates the technical refinements.

Collision Avoidance in the Fork Tip

Reliably preventing collisions involving driverless forklifts is an ideal area of use for the USi-safety ultrasonic sensor system. As the ultrasonic technology is resistant to dirt, temperature, air currents, and humidity, it significantly expands the area of use for these automated guided transport systems (AGT). In addition, USi-safety is even able to safely monitor the dead band just ahead of where the fork arms enter the pallet—a challenge that none of the usual safety-certified systems have been able to cope with up to now. A specially developed algorithm prevents cross-talk between multiple automated guided transport systems equipped with USi-safety.

In the chemical industry, tanks as long as 20 meters can be moved around the site with correspondingly large automated guided vehicles (AGV). Additionally, the routes are used by other vehicles, and also by people, either on foot or riding bicycles. The AGV is controlled using an electronic connection to a tag track. However, long tanks require a correspondingly large radius when cornering and—especially at these points—lateral collision protection. Several USi-safety ultrasonic sensors are distributed on each side of the vehicle. The very compact ultrasonic transducers can be mounted in places where other types of sensor would not fit, for example in the wheel area. The sound beam functions as an acoustic “sensor,” which enables noncontact control of the side area during transport. The devices reliably detect all obstacles in a defined safety area. If required, the safety outputs intervene in the vehicle control system.

Safe Overhead Conveyors in Hospitals

Automated guided transport systems can be found in many hospitals. This specific application involves an overhead conveyor with metal rolling containers in which materials such as laundry, medicine, and food are moved to their destination. The AGT system moves through the supply passages in basement floors, picking up rolling containers and transporting them to the required station through special shafts. The USi-safety devices are ideal for integrating into the chassis of the AGT system. The freely positionable ultrasonic transducers are fixed at a predefined angle on the right and left using customized mounting sets. To prevent the transducers from separating when the container holder rotates, they each seal with the bottom edge of the switch cabinet.

Machine Safeguarding in the Wood Industry

Usually, machines are safeguarded by photoelectronic light curtains. However, wood dust or other particles flying around in the air, for example, can cause false alarms and the machine switches into the safe state. The light grid must be cleaned and the machine restarted manually in order to continue with the process. Due to ultrasonic technology, the USi-safety, used as a "sound curtain," is insensitive to wood dust and other particles and can withstand demanding environments. Unlike optical sensors, the USi-safety does not need to be kept clean, nor is the production process unnecessarily interrupted by false alarms—and the machine is still reliably safeguarded. At the same time, the system offers the advantage that fixed machine parts can be taught-in via teach-in function and used for manipulation protection. If this reference target is no longer recognized due to manipulation, the system switches to the safe state.

Personal Safety in Lane-Guided AGVs

Lane-guided AGVs follow a lane applied on the ground and transport goods from one station to the next. In this process, it can happen that the paths of people cross the specified transport paths of the vehicles. In such areas, collisions between the AGVs and people must be avoided to ensure both personal protection and uninterrupted transport. For this purpose, the detection range of the ultrasonic transducers can be quickly and easily adapted to the conditions via the parameterization software. In addition to safe OSSD outputs for the safety field, the sensor system also has one signal output per channel, for example to reduce the speed of an AGV or to issue a warning signal.

You Might Also Be Interested In …

If you want to use the outstanding features of the USi-safety in non-safety or low-level safety applications up to category 2 PL c, the USi-industry is the right choice for you. The USi-safety's sister system offers a cost-efficient solution for many automation tasks.