Precise Detection of Parts for Car Body Construction

Compact Laser Profile Sensor Provides Height Profile and 2-D Surface Image

The Application

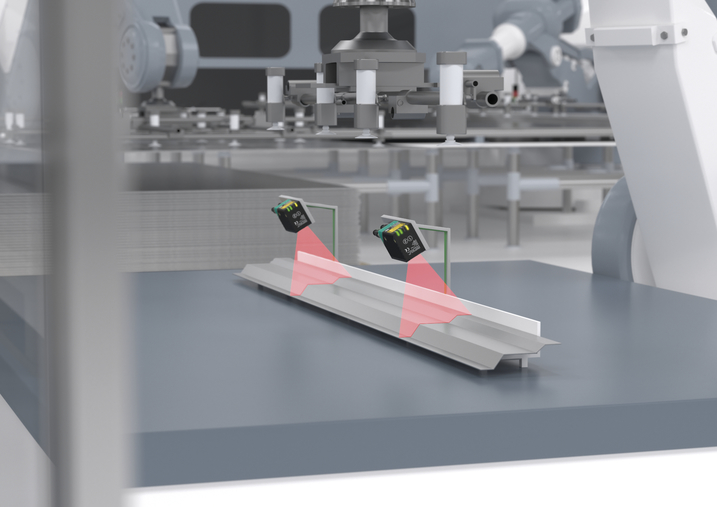

In the automotive industry, high demands are placed on the accuracy of the fit of parts during body construction. The formed sheets have to meet strict tolerances in three dimensions. Accuracy to specifications is monitored by spot checks in the press shop: a robot gripper removes a formed part from the process and conveys it to the inspection station. The height profile is recorded with the required precision by sensors. From there, the data is transmitted to the respective quality assurance system, which compares it with the defined specifications.

The Goal

The sensor has to detect the workpiece with high precision. Detection must not be impaired by reflective surfaces, as is often the case with metal parts. The integration of the device into the higher-level system is also particularly important. For easy implementation into the programming system, the sensor should have an API and provide full access to the parameterization as well as the output data. In addition, an Ethernet TCP/IP interface is required to connect it directly to an IPC.

The Solution

SmartRunner Explorer

The SmartRunner Explorer laser profile sensor captures the height profiles with great precision. Reflective surfaces have no influence on this. The device offers both an Ethernet TCP/IP interface for connection to an IPC and a supplied API. It allows full access to all parameterization and output data. By means of an example, which is also supplied, it can be easily integrated into a C# development system. A graphical user interface is available for easy parameterization as well as for the analysis of height profiles and 2-D surface images.

Technical Features

- Height profile output with 960 value pairs in world coordinates

- 2-D image output with 1,280 × 960 pixels

- Measuring range: X 40–160 mm/Z 60–350 mm or X 40–345 mm/Z 100–700 mm

- API for easy integration

- Interfaces: Ethernet TCP/IP, I/O

- Maximum scan rate: 30 Hz

- Laser class 1, degree of protection (IP67)

The Benefits

The SmartRunner Explorer is the only laser profile sensor on the market that offers not only a height profile output, but also the option of capturing a 2-D surface image. Integrated LEDs illuminate the objects to be detected. The image can be used to document faulty components and can be read out via the TCP/IP interface. Compact design and a swiveling connector allow mounting even in particularly confined spaces. The size of the detection area, which normally also shrinks with a reduced design, is fully preserved by using a mirror.

At a Glance

- Reliable and precise detection of the parts, even with reflective surfaces

- Compact design and flexible mechanical integration for easy installation in limited spaces

- Simple integration into the programming system

- Output of height profile and 2-D surface image

- Graphical user interface Vision Configurator for convenient parameterization as well as image and line visualization

+65 6779 9091

+65 6779 9091