The U-shaped WCS read heads scan the stainless steel or laminate code rail photoelectrically and without contact. Different versions are available to users depending on the application. The outdoor version, for example, is particularly robust, while the WCS read head with integrated heating is ideal for use in particularly cold regions.

The read heads have internal light intensity control so they can reliably determine position values, even in difficult environmental conditions and despite contamination. RS-485, SSI, CANopen, IO-Link, PROFINET, EtherCAT, Fail Safe over EtherCAT (FSoE), or EtherNet/IP interfaces can be used to transmit data to the controller.

Safety Guaranteed

The proven WCS is also available for safety applications. For this purpose, two safeWCS/PUS read heads are combined with the safe evaluation unit (Position Unit Safe, PUS). This safe linear positioning system enables safe position and speed detection up to SIL 3 and PL e. Two safeWCS/PUS read heads are used for this purpose, which are mounted one behind the other on the code rail. To ensure separate redundant signaling, one read head is parameterized for forward movement and one for reverse movement. The safe evaluation unit processes and evaluates the redundant signals from the sensors and transmits them to a safe controller.

Special Options

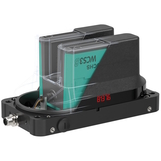

The WCS outdoor option is a read head with a protective housing. It was specially developed for applications in challenging environments. Its rugged housing with IP69 degree of protection makes the read head resistant to dust, moisture, shocks, and vibration. This means it can also be used in environments with high-pressure cleaners or where the WCS comes into contact with substances such as saltwater, acids, and alkalis.

In case of malfunction, easy maintenance of the WCS read head is possible because the indicator LEDs and the optional display are easy to read through the translucent housing. If the system has to be installed in tight spaces, the connection options can be arranged flexibly: the connectors can be installed in three different locations.

For special installations, Pepperl+Fuchs offers the WCS read head with a display option. A seven-segment display is integrated into this read head. The display can be easily rotated by 180° so that the data is clearly visible directly on the read head when the installation is suspended or upright. System setup and troubleshooting have also been simplified. The display can show the current position value, diagnostic functions, and can draw attention to dirty or damaged code rail segments.

If an application requires an especially long distance, the special WCS Extended version makes it possible to cover a distance of up to 629 m. Assembly and integration of the two standard code rail segments are flexible. The extended read head can read the extended distance without additional programming.

For extreme temperatures, the WCS read head with heating option is an ideal solution. An integrated heating element permits an extended operating temperature range. Also available with the outdoor version, this enables the systems to be used in environments with temperatures as low as –40 °C. The combination of an integrated heating element, supplied via the read head, and a smooth housing surface makes this possible. Commissioning in both ice and snow is also feasible and it also protects against the risk of condensation due to rapid temperature changes from cold to warm.

The WCS read head portfolio includes a speed option. The WCS3B read head with velocity output uses an additional switching output to signal that a speed limit has been exceeded.

+65 6779 9091

+65 6779 9091