Beyond Vision

Unique combination of laser light section method and 2-D vision technology in a single device.

Laser Profile Sensors with SmartRunner Technology

They create space for completely new application possibilities: The sensors of the SmartRunner family combine the powerful laser light section method with 2-D vision technology in just one device and therefore master all tasks in the field of profile detection and inspection. The laser profile sensors are each optimized for a specific application area—the “Matcher” stands for reliable profile comparisons, the “Detector” for precise area monitoring and the “Explorer” for height profile output.

Get to know the sensors of the SmartRunner product family and find the right laser profile sensor for your individual application!

Applications and Areas of Use

A sensor for every application: With the laser light section technology, the sensors of the SmartRunner series master numerous tasks in the field of industrial vision:

Height profile detection on a laser line

Check for the presence of objects

Check for correct number of objects

Shape matching with reference profile or contour

Position check of objects and output of position data

Monitoring of areas

Dimensioning of objects and output of measurement data

Benefits

Robust Detection

Flexibility in Production Adjustments

Convenient and Quick Assembly

The Innovative SmartRunner Technology

In Combination, an Innovation

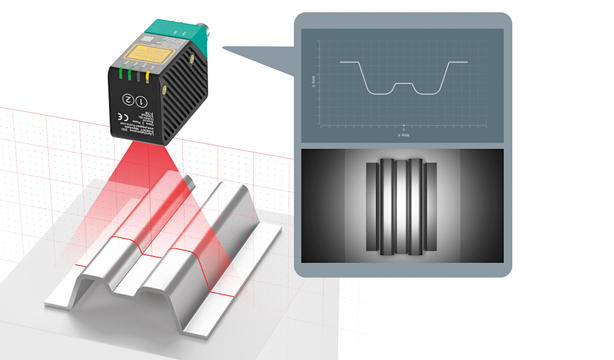

The SmartRunner technology is a unique combination of laser light section technology and a 2-D vision sensor with integrated LEDs. The result is plug-and-play sensors for special applications or flexible raw data sensors that offer completely new applications for demanding detection tasks and enable efficient, future-proof processes. Get to know the technology …

The SmartRunner Explorer offers the unique combination of height profile and 2-D image output in one compact sensor. Using laser light section technology, the sensor reliably detects the height profile of an object—regardless of the surface and lighting conditions. It then provides the raw data of the height profile so that the user can process it individually. As a unique feature, the SmartRunner Explorer additionally outputs 2-D surface images, simplifying diagnosis and documentation of line data.

The laser profile sensor can be easily integrated into PC programs via Ethernet TCP/IP and the supplied DLL for C# or alternatively via C and Python wrappers. The GenICam and ROS interfaces also enable universal access to data and parameters as well as to a variety of programming modules from software libraries. This saves users time and money when implementing individual applications.

Typical Applications:

- Measurement and volume detection

- Quality control

- Individual applications by using raw data

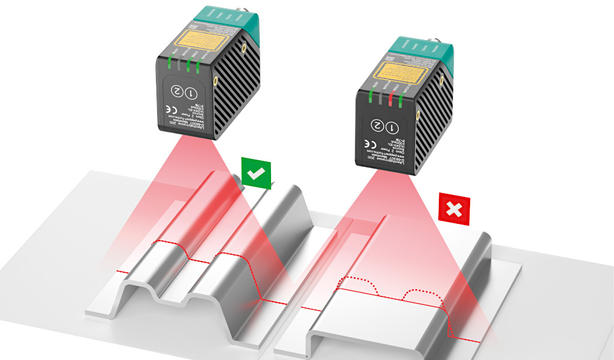

The SmartRunner Matcher ensures reliable profile comparisons at all times, regardless of surface condition, lighting or ambient light—even with particularly low-contrast objects. To do this, the sensor verifies the detected profile, the correct position and the optimum distance of an object and compares the detected profile with the previously taught reference profile via trigger. The integrated evaluation unit is programmed to report deviations from the reference profile, so that the sensor outputs a “good” or “bad” signal depending on whether the profiles are identical or different.

The sensor can be commissioned quickly and easily: via the Vision Configurator, by DataMatrix control code or by guided operation and parameterization with the software wizard, which enables step-by-step configuration without a manual. In addition, the user can freely define the object and displacement tolerances and output position data separately. The SmartRunner Matcher therefore offers the optimal solution for robust and cost-efficient presence, completeness and position detection of components.

Typical Applications:

- Detection of small parts such as rivets, screws, and clamps

- Completeness checks for pens, pills, etc.

- Position testing and output for boxes, pallets, and other objects

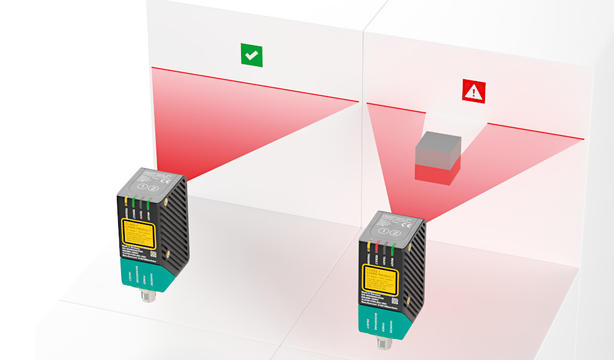

The SmartRunner Detector offers the optimal solution for high-precision monitoring tasks. Whether highly reflective, transparent or absorbent surfaces—due to the additional background evaluation, the sensor reliably detects even objects that are not recognizable at first glance. The sensor responds immediately to interfering objects in the detection range due to the interrupted background line, therefore ensuring the user absolute process reliablility.

The SmartRunner Detector can be easily parameterized via DataMatrix control codes, via the parameterization software or via plug-and-play. The laser line just only has to be aligned to a fixed background such as a wall and taught in. Alternatively, teach-in can also be performed via keystroke or via the parameterization software in an empty room. In addition, the SmartRunner Detector offers the option of freely defining object sizes in a specific monitoring area, the so-called region of interest (ROI), in order to avoid false alarms caused by external influences.

Typical Applications:

- Area monitoring for the protection of sensitive machine parts

- Inspection of overlapping components for quality control

- Access monitoring

More Use Cases for SmartRunner Matcher

Ensuring Reliability in Ready-Meal Production

Plastic trays divided into several small compartments are often used when producing ready meals in the food industry. Filling the individual compartments in the plastic tray and carefully separating the different meal components is an essential prerequisite for acceptance by the customer and for properly sealing the container. In the case of a defect, the product cannot be sold, and the meal must be discarded. Checking that the plastic trays are in the correct position requires a reliable, quick, and easy-to-install solution that supports a quick and efficient filling process. The SmartRunner Matcher offers the ideal solution for checking the position of the plastic trays.

Smooth Material Feed in Production Plants

An uninterrupted supply of raw materials is crucial for maintaining cost-effective operations in production plants. The materials, which can vary in color, are transported to the machine in workpiece carriers. Before the materials are picked up by the robotic system, it is necessary to check whether the materials are present (presence check) and whether the materials are in the correct position (position control). Efficient operation without plant downtime or production waste is always the top priority. With the SmartRunner Matcher light section sensor, both detection tasks can be performed in a single step.

Contact Us

Do you have any questions on the SmartRunner product family, or do you want to receive more information? We are happy to help! Simply fill out the contact form and send us a message.

Further Information

Further Information

+1 330 425-3555

+1 330 425-3555