Mobile Equipment Connectivity—Robust Connections for Mobile Sensors

Customized DT connectors from DEUTSCH are at the center of Pepperl+Fuchs' MEC series for mobile equipment.

Mobile applications bring connection technology to its limits: heat, cold, vibration, and UV radiation take their toll as well as oil splashes or road salt residues. Highlighting our product range “Mobile Equipment Connectivity” (MEC), Pepperl+Fuchs introduces a new series of connectors for wiring sensors and actuators in these challenging environments. The MEC series features popular DT connectors from company DEUTSCH combined with special customizations by Pepperl+Fuchs for mobile applications. The result is a durable connector designed for extreme resilience and long life.

DEUTSCH connector meets sensor expertise

DT connectors are the best choice for mobile applications. The easily pluggable, very reliable snap lock and proven sealing concept ensure operational safety of vehicles and mobile machinery. Pepperl+Fuchs has further enhanced these DT connectors by completely molding them. This mechanical full encapsulation of otherwise exposed cable cores improves the connector’s ability to withstand salt, UV radiation, oil, or water ingress. Increased strain relief and a strong corrugated loom latching mechanism further boost the ruggedness of these connectors. A slim and space-saving design makes machine design easier.

PUR-O cable quality and connection options

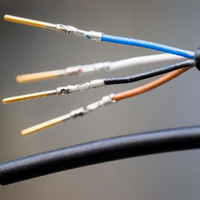

Mobile equipment sensor cordsets feature high-quality cable cores

The cable cores molded to the DT connectors feature PUR-O quality for mobile applications. The durable sheathing type and molded connector bodies allow assembled DT sensor/actuator cables to be used in a wide -50 °C … 105 °C temperature range. For highest flexibility, many different assemblies of DT sensor/actuator cables are available. Users can select from DT to DT, DT to M8, DT to M12, or versions with flying leads.

In addition to the DT connectors, the MEC series includes AMP style connectors and numerous variants of M8 and M12 sensor/actuator assemblies based on high-quality cable sheathings. Here, unshielded and shielded versions for typical CANopen automotive applications are available.

For connection of hydraulic, pneumatic, and electromagnetic actuators, type A valve connectors developed for outdoor use are an ideal solution. They feature a robust silicone seal, durable stainless steel screw, and built-in noise suppression, which supports safe operation of machinery. Translucent housing material enables clear status indication even under difficult lighting conditions.

Single source equipment for mobile sensing applications

The MEC portfolio includes junction blocks for efficient wiring. These connect up to 16 sensors or actuators and are developed with a special focus on outdoor applications: their foam rubber surface absorbs irritating vibration noise that may occur when mounting junction blocks to vehicle chassis or body parts. The metal threads of the connector sockets offer a surface coating made for exterior use. Special O-ring seals make the sockets resistant to the most challenging outdoor environments while the trunk cable reduces installation work to a minimum and helps avoid incorrect wiring. This makes the junction blocks an ideal alternative to costly parallel wiring or to cable harnesses for small quantities.

“With the MEC series, we bridge the gap between factory automation’s characteristic round plug connectors and automotive industries. This focused portfolio is a real advantage for users, as Pepperl+Fuchs provides them with sensors and custom-fit connection technology for mobile equipment—from a single source,” comments Business Manager Roland Gubbels.

At a glance

- Custom-fit for mobile applications: fully molded, encapsulated DT connectors

- UV and oil resistance plus wide -50 °C … 105 °C temperature range for extreme outdoor applications

- Strong corrugated loom latching mechanism for additional protection in challenging environments

- Rigorous testing and quality standards with in-house production and zero-fault tolerance

- Custom designs and additional components available for diverse applications

- Single source sensor and connection technology enables quick integration into applications

+27 87985 0797

+27 87985 0797