Paving the Way for Fully Digital Plant Control

Improve Device Status Visibility and Adapt to the Future with Ethernet-APL

The Application

The customer is a research-based pharmaceutical company with around 46,000 employees worldwide. It is one of the three main players in its field on the global market. In its power plant in one of its production facilities, the current control system reached the end of its service life and needed to be replaced. Communication based on PROFIBUS PA provides process and diagnostic information from instruments that are also installed in Zone 2 hazardous areas.

The Goal

The company is known for being an early adopter of new technologies and wanted to prepare for Ethernet-APL in order to convert its plant to fully digital communication, from field devices to engineering to control and maintenance systems. In other words, the move to Ethernet-APL was an important step into the future.

They envisioned a system with reduced complexity that would ensure a high degree of interoperability between different technology generations. They hoped for maximum transparency and a detailed insight into all aspects of operation and performance while maintaining independence of specific suppliers and legacy solutions. Additionally, the protection of investments in the existing infrastructure, including the continued use of existing PROFIBUS PA devices, needed to be ensured. Lastly, a standards-based transition to a digitalized plant control system was highly desired.

The Solution

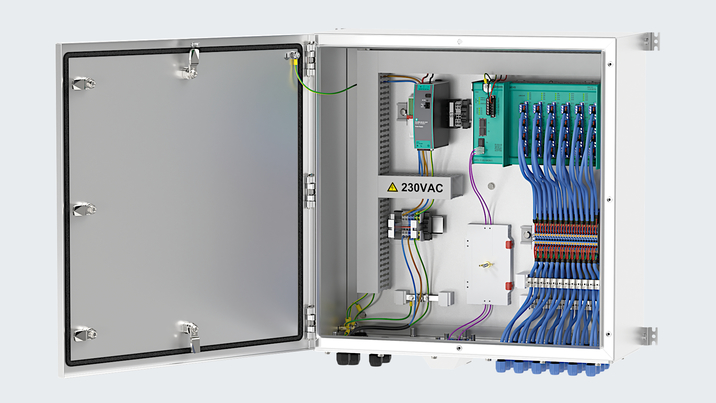

The Ethernet-APL rail field switch provides seamless connectivity and automatically adapts communication on each port to PROFIBUS PA or PROFINET over APL, while the switch’s web interface delivers device and physical layer information. This allows a device installer to document the execution of work orders, e.g., the user can verify proper communication after replacing a device. The installation of the Ethernet-APL interface serves to prepare the entire system for a transition from the existing device communication to a future with comprehensive insights into device and plant operation.

In addition, Pepperl+Fuchs was able to provide a standardsbased transition to a digitalized plant control system in close cooperation with the customer. The required device communication was confirmed in a plug test between the customer, the DCS manufacturer, and Pepperl+Fuchs, which validated that even older PROFIBUS PA devices can communicate seamlessly.

Technical Features

- Preparation for the joint use of PROFIBUS PA and Ethernet-APL instrumentation

- Ethernet-APL field switch in certified, stainless steel enclosure according to the customer’s specifications

- Safe operation in Zone 2 explosion-hazardous areas

- Surge protection

The Benefits

The result is a control and asset management system where the user interface is the same regardless of the communication used, improving the quality of service and the usefulness of the information provided by the system. Continued use of existing cabling and field devices protects the investment in instrumentation. The migration path is now seamless as new and added Ethernet-APL devices can operate side by side using the same communication infrastructure.

The drastically improved level of information enables workflows for predictive maintenance while improving plant availability and yield, which is expected to increase significantly.

At a Glance

- Protection of existing investments in field devices and system cabling

- Reduced risk in the planned transition to Ethernet-APL

- Extended communication with the system on-site and off-site

- Improved device diagnostics for preventive maintenance

+27 87985 0797

+27 87985 0797