Efficient Navigation of Automated Guided Vehicles: New PGV Positioning Systems with TCP/IP or EtherCAT® Interface

Pepperl+Fuchs now also offers variants of the PGV positioning system with an integrated TCP/IP or EtherCAT® interface.

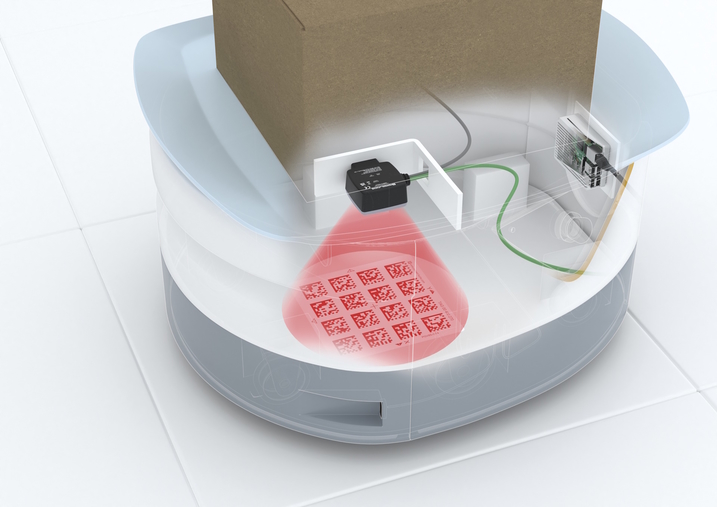

Automated guided vehicles (AGVs) are used primarily in intralogistics, but also in numerous other industrial sectors, to transport goods from A to B. Reliable positioning systems are required to ensure that they always reach their destination safely.

The F213 version of the PGV (Position Guided Vision) with integrated TCP/IP interface is specially designed for the camera-based guidance of so-called bots and small AGVs. The particularly compact design is ideal for the requirements of confined installation spaces and can be installed in a space-saving manner. With its design depth of just 35 mm, the PGV*F213* read head fits perfectly into slim vehicles and represents a very economical solution.

Like all PGV read heads, the PGV*F213* consists of a camera system with an integrated lighting. The compact read head variant uses red light and tracks Data Matrix codes and tags on the floor. Users receive the codes either as self-adhesive code tape or—for highly demanding environments—on robust metal code bars.

Direct Connection to PC via TCP/IP Interface

The space-saving version of the PGV is now available with an integrated TCP/IP interface. While it was previously necessary to connect to a controller to configure the read head, users can now connect the PGV*F213* positioning system directly to a PC or even a single-board computer. This makes commissioning quick and easy while also eliminating the need for an additional cost-intensive controller for the navigation of the AGVs. In applications where many bots are used, this offers a decisive advantage in terms of cost-effectiveness.

Real-Time Positioning for Fast AGV Traffic

In large warehouses, numerous AGVs and bots are often in use at the same time. To avoid collisions, the routes of the vehicles must be perfectly coordinated and reliably monitored in real time. This is the only way to ensure that the AGVs can move simultaneously and at full speed with just a few centimeters between them. The PGV*F213* uses a synchronization pulse and timestamp on 2-D images to enable high-precision synchronization between the control of the individual bots and the higher-level master control system.

Particularly Fast: PGV F200 Now Also with EtherCAT®

The all-around solution: PGV*F200*

The PGV*F200* is the ideal solution for users who want to navigate their AGVs not only with Data Matrix codes and tags, but also on colored tape or paint lines. The all-around solution in the PGV portfolio can flexibly read all available positioning targets—individually or in combination. For maximum flexibility, this PGV variant is available with a broad selection of integrated interfaces. These include CANopen, EtherNet/IP, PROFIBUS, PROFINET, and RS485. The PGV*F200* with integrated EtherCAT® interface is a new addition to the portfolio. Data is transmitted reliably and in real time from the PGV read head to the control system. In addition to the position values, the data also includes information about the current status of the Data Matrix code tape. The PGV*F200* with EtherCAT therefore stands for maximum process reliability.

Highlights of the PGV*F213* Positioning System

- Positioning system with TCP/IP interface for the camera-based guidance of small bots and AGVs

- Compact read head with 35 mm design depth for confined installation situations

- Quick and easy configuration via (single-board) PC without higher-level control system

Highlights of the PGV*F200* Positioning System

- All-around solution for all available positioning targets: Data Matrix codes and tags, colored tape and paint lines

- Broad selection of integrated interfaces for maximum flexibility

- EtherCAT interface allows real-time data transmission and maximum process reliablity

+27 87985 0797

+27 87985 0797