The absolute benchmark.

Proven system with maximum precision – even in extreme weather, dirt, and harsh environments.

WCS Absolute Positioning System

Flexible Integration

Rugged Design

Simple Setup

Precise Absolute Position Detection

Due to its modular design, the position encoding system can be adapted to any application or environmental situation. It always consists of a read head, a code rail and the appropriate mounting system. The read head is available with various options, such as the WCS Outdoor option for harsh environments or the WCS Extended option for particularly long distances, which can also be combined with one another. If the read head and code rail are selected, three different mounting systems are available. For safety-related positioning applications, Pepperl+Fuchs combines the advantages of the WCS positioning system with a safe evaluation unit (Position Unit Safe, PUS).

Robustness and Precision in All Conditions

Learn More

Learn More

Learn More

Learn More

Learn More

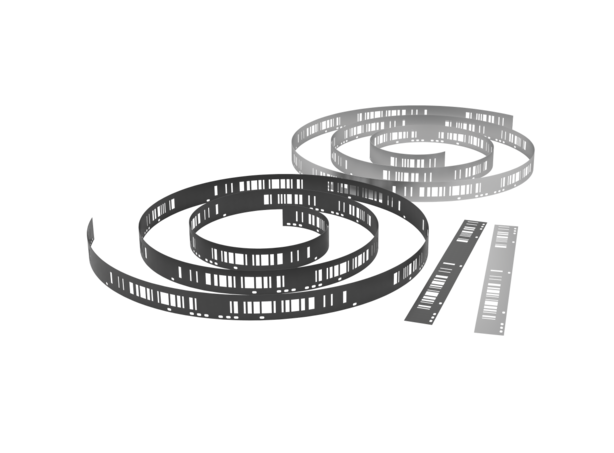

Code Rails and ID Pads for Harsh Environments

Laminate code rails:

Laminate code rails from Pepperl+Fuchs are made of a tear-resistant polyester laminate that is not affected by oils, greases, and solvents. Because of its resistance to chemicals, acids, alkalis, and aggressive gases, the code rail can also be used in electroplating applications.

Stainless steel code rails:

Stainless steel code rails from Pepperl+Fuchs are corrosion-resistant and can be used in temperatures ranging from -40 °C to 80 °C. They are resistant to flying sparks in welding shops and heavy contamination. In combination with the WCS Outdoor, safe and reliable positioning is guaranteed.

Detection with ID Pad:

Mounted on moving objects, the ID pad allows a read head to identify a chassis as it passes by. This enables fine positioning and is rugged for extreme environments.

Mounting Systems

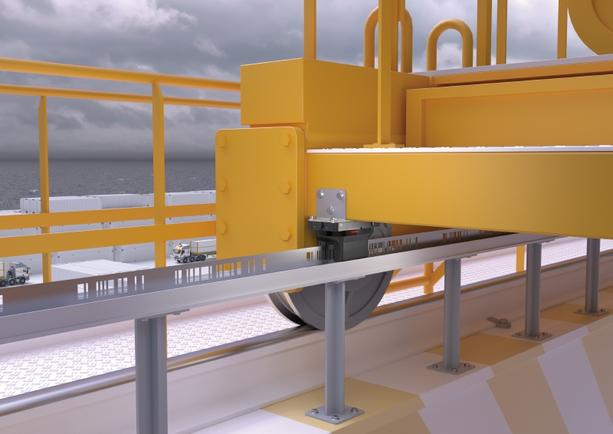

Exact Positioning in All Weather Conditions

Exact position detection is ensured, even with temperature fluctuations. With the combination of Outdoor and Extended options, long distances are no longer a problem in modern harbor operations. This makes it possible for container cranes to move containers from one location to another over a distance of a maximum of 629 meters, ensuring that the crane is positioned with millimeter precision. As can be seen from the illustration, the position of the trolley during container loading can also be determined precisely by using a WCS. Both are based on durable stainless steel code rails using a WCS read head.

The WCS Outdoor with a special protective housing was developed for extreme outdoor applications—salt water, salty air, or any other type of humidity. With protection up to IP69, it offers the highest degree of sealing. In addition, the impact-resistant read head is immune to hail and provides protection against mechanical influences.

Due to the protective housing of the read head, the Outdoor Version of the WCS is resistant to aggressive substances—this also applies to the available plastic code strips with special coating. Even complex routes, curves, gradients, and inclines are no problem for the WCS.

Resistant to Acids and Alkalis

High temperatures can occur in galvanic plants, and the air is often saturated with vapors from the solutions. In this harsh environment, workpieces are normally attached to a metal frame and automatically transported to the immersion baths with extremely aggressive solutions.

Contact Us

More Information

More Information

- Position Encoding System (WCS) Take a look at our product portfolio

- Reading Heads Discover different versions of WCS reading heads

- Interface Modules Take a look at the wide range of interface modules

- Mechanics Learn more about the WCS mechanics

- Accessories Find the right accessories for your WCS system

Downloads

Downloads

+27 87985 0797

+27 87985 0797