Types of Ultrasonic Sensors

Cubic sensors—versatile in respect of design and application

The series L2 ultrasonic sensors feature both a large range spectrum and a rotatable sensor head.

Our broad cubic sensor portfolio offers the ideal solution for almost every measuring task. Special designs and features such as minimized blind zones, large ranges, and extremely rugged designs open up maximum flexibility in application solutions for the user. Series F77 ultrasonic sensors offer a wide range of features and setting options such as IO-Link, sound beam switch, synchronization, minimal blind zones, and a high range of up to 31 in. Series F12 ultrasonic retroreflective sensors are ideal for measurements in especially small feedings such as in bottling machines or in shaking conveyors, while ensuring the highest degree of detection reliability by means of independent sensor synchronization. The series L2 ultrasonic sensors feature both a large range spectrum and a rotatable sensor head, enabling special installation options. With IP67 protection, they are ideally suited for use in harsh environments. Depending on the intended use, there are additional cubic designs available.

Cylindrical sensors—maximum flexibility for diverse applications

Thanks to their standard design, cylindrical ultrasonic sensors M12, M18, and M30 can be easily integrated in every machine environment. Stepped or angled transducers as well as short designs expand the scope of integration. Besides, the portfolio is characterized by application-specific solutions for hygienic areas or for aggressive chemicals, and provides maximum flexibility for an ideal application solution—for both standard and special applications.

Chemically resistant ultrasonic sensors

Increased material resistance for maximum availability even under extreme operating conditions—this is offered by UBC series and UCC series ultrasonic sensors. Thanks to the highest protection types, all surfaces that are exposed to chemicals and atmospheres are hermetically sealed against penetration of aggressive chemicals—for example, acids and alkaline solutions.

Hygienic sensors—for use in product-contact zones

Hygienic sensors come with a stainless steel, hermetically sealed and hygienic design and food-grade materials according to the standards of FDA, ECOLAB, and EHEDG. The sensor head and all other housing parts are laser welded and hermetically sealed against penetration of vapour or liquids. The gapless design ensures that cleaning agents run off completely, and that bacterial growth is prevented. The highest level of product and process reliability is ensured during the filling and packaging process of groceries and drugs, making it the ideal sensor type for use in chemistry and process engineering due to the use of high-resistance materials.

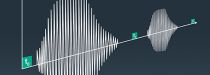

Double sheet sensors—safe process operation and high plant availability

A multilayer feed of materials such as paper, cardboards, sheets, foils, or labels can lead to machine downtime, process disruptions, and waste. Double sheet sensors prevent defective material feeding und ensure safe processes and high plant availability. This technology is applied as double sheet, label, and splice control.

+46 303 246070

+46 303 246070