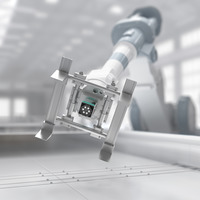

Chassis Inspection in the Automotive Industry

Vision Camera for Inspecting Parts during the Assembly

The Application

In automotive processes, there are strict quality controls to produce cars with the highest quality and avoid improper stops on the assembly line. Proper inspection of all manufacturing steps is essential to achieve this level of productivity and excellence.

The Goal

The application is designed for the inspection of parts in the assembly process, to validate the presence of these parts, which are mounted directly on the vehicle chassis, through a robotic process or even manually by specialized operators. Such parts as screws, fasteners, plugs, etc. are inspected comprehensively and with maximum precision.

The Solution

VOS Vision Sensor

Pepperl+Fuchs VOS vision sensors deliver fast and accurate results in measurement, position and quality control, detection and comparison, code identification, text recognition, and many other functions—all in one device. All these features would typically require a complex and expensive vision system, which is not the case with the VOS due to its flexibility.

The vision sensor has been implemented with integrated lighting on the assembly line at an inspection station, where it will be possible to verify the presence of these parts using trigger sensors that indicate the particular parts to be inspected to support the correct sequence. All data is sent to the customer's internal system via industrial communication, using protocols such as EtherNet/IP, PROFINET, Ethernet TCP/IP, and RS232. Additional HMI interfaces have been developed for local visualization of the inspection.

The solution also features free and user-friendly programming software for easy configuration, optimizing commissioning time.

Technical Features

- Identification of 1-D and 2-D codes

- Resolution up to 5 mega pixels

- Identification distance up to 2000 mm, depending on application

- Communication in RS232, Ethernet TCP/IP, EtherNet/IP, and PROFINET

- Lighting accessories available

- Programmable I/Os

The Benefits

In this project, the VOS vision sensor contributes to the quality control of the final products and the manufacturing process itself by indicating the presence or absence of parts that make up the set. Due to the flexibility of the vision sensor, there were no difficulties or excessive time required to execute and implement it in the plant, which was of great benefit to the area and the customer overall.

At a Glance

- Fast and accurate results in code identification, detection, position control and more, all in one device

- Similar setups typically require a complex and expensive vision system

- Integrated lighting + triggers sensors for presence verification

- Simple configuration with free and user-friendly programming software

+1 330 425-3555

+1 330 425-3555