Battery Storage

Powerful batteries are needed to store climate-neutral electricity from wind power or photovoltaic plants. The demand for battery storage is therefore continuously increasing—both for network operators and in private households.

Pepperl+Fuchs offers the right sensor technology to automate all tasks in battery manufacturing. From the battery cell to the inspection and assembly of battery modules, the sensors ensure maximum quality and efficient processes.

Discover a comprehensive overview of our sensor solutions for battery manufacturing and find the right product for your individual challenge!

Our Product Highlights for Battery Manufacturing

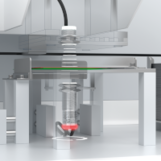

During the manufacture of battery cells, electrode and separator foils are alternately stacked on top of each other. The need for monitoring in this process is high—for example, the feeding of double sheets must be prevented. In this application, the M18 ultrasonic double sheet sensor detects even thin and reflective foils.

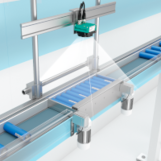

Pepperl+Fuchs industrial vision products solve various tasks in the manufacture of battery modules. For example, the universal code reader VOS-I ensures that all required battery cells are present. This vision sensor reads even small codes on curved surfaces quickly and reliably.

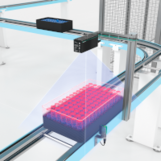

To ensure consistently high quality, battery modules must be reliably inspected. The SmartRunner Explorer 3-D, for example, is used for this task: The stereo-vision sensor from Pepperl+Fuchs performs a fully automated quality inspection of the battery modules using a high-resolution 3-D point cloud image.

+61 3 9358 3400

+61 3 9358 3400