At Long Distance.

High-performance identification systems for long ranges and maximum flexibility.

RFID read/write devices with UHF technology

Features

High Compatibility for Easy System Integration

Fully Geared to Industrial Applications

Quick Information Gathering With Multitag Reading

360°—Explore the Mid-Range Version F190

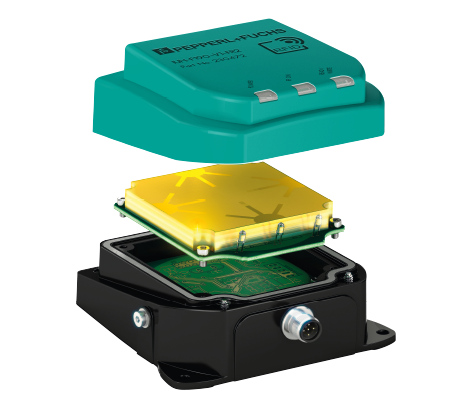

Our UHF read write/heads are ideally suited for installation in challenging environmental conditions. Their rugged exterior and sealed electronics reliably protect them against all kinds of wear and tear, including high temperatures. Possible space restrictions are no longer an issue thanks to the device design of our UHF read/write devices: the UHF antenna is mounted inside the compact housing. This approach eliminates the need for error-prone extra components like coaxial cables while at the same time allowing for easy installation in tight spaces.

If you want to learn more about RFID technology in general, we recommend a visit to our "RFID Hub." This special website is a knowledge base for RFID. Get answers on frequently asked questions and learn about RFID components …

Industrial RFID Technology

Robust UHF Read/Write Devices for Industrial Environments

To realize reading distances of more than 2 m, F192 extends the product family with outstanding features. With a range of up to 6 meters, this UHF read/write device is especially suitable for applications where long distances need to be covered. It is able to read and write on up to 200 tags at the same time, allowing an extremely fast throughput and significant productivity increase in material handling and intralogistics processes.

Use Cases

More Efficiency in Material Handling

Efficiency is top priority in intralogistics. Goods need to be transported to their place of destination fast, safe, and without any misassignment. For applications where it comes down to mounting space and where reading distances from 1 m to 2 m are sufficient, F190 is ideal. Transmitting data in one bundle, information from multiple tags can be transmitted to the read/write device in a single step.

Reliable Processes in Automotive Production

Automobile production can be controlled by tags that are mounted on skids or directly on vehicles. In addition to reading the vehicle ID, the write function enables the modification of information for downstream production steps on the tags. Even in challenging environments, like they frequently occur in the final assembly, our UHF read/write devices (e. g. F190) convince with their extreme reliability and flexibility.

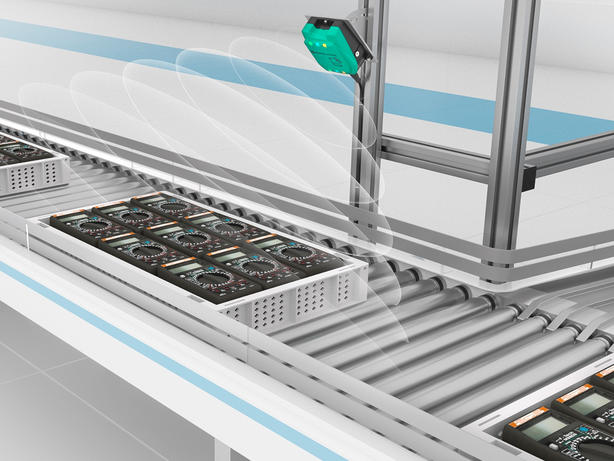

Electronic Kanban systems in automotive manufacturing rely heavily on identification technology. In this example, an F191 UHF RFID read/write with integrated IO-Link interface checks whether the trays are correctly aligned and whether the right trays are made available to the robot.

Contactez-nous pour de plus amples informations

Simply send us an email to receive more information on the UHF read/write devices and RFID technology.

Downloads

Downloads More Information

More Information

+32 3 644 25 00

+32 3 644 25 00