Inductive sensors with AS-Interface

Locating a defective sensor in system concepts with conventional wiring is quite difficult. Machines usually have to be shut down for long periods while the cause of the fault is located.

In a modern system concept such as the AS-Interface, special integrated circuits lend the sensors a certain degree of “intelligence” and extend their range of functions. These inductive sensors are able to monitor both themselves and their supply cables and exchange data with a higher-level unit such as a PLC.

Failure warning display

In practice, inductive sensors are positioned so that the distance between the actuating element and the active surface is about 50 % of the rated operating distance sn. The switch is guaranteed to function correctly within the assured operating distance sa = (0 to 0.81) • sn. If the actuating element is located between sa and the actual operating distance sr, a failure warning display bit (data bit 1) is set so that maladjustments can be detected early before a detection error occurs.

The default value of data bit 1 is “1”, which means “normal state”. If the failure warning display is set, the value of this data bit is “0”. This value remains the same until the inductive sensor is fully damped or the target has approached to a point closer than sa and is then removed again, i.e. sr + hysteresis.

Designs

AS-Interface inductive sensors

We offer inductive AS-Interface sensors with the following designs:

Cylindrical

- From M12 to M30, flush and non-flush, in stainless steel enclosure with V1 connector and multiple LEDs

Cuboid

- Can be connected via a terminal compartment like a VariKont

- Can be connected via an M12 connector like a VariKont L

- Can be connected via a terminal compartment like a VariKont M

- Can be connected via a terminal compartment like an FP

- Screw-on F design, with 2 m round cable

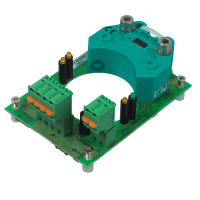

Position sensors

- F25 series with circuit board design for installation in an enclosure. Connection via plug-in terminals

- F31 series for direct installation in normal drives. Connection via cable or terminals

+45 7010 4210

+45 7010 4210