Future is Now.

Data exchange from sensor to PLC and beyond—standardized and transparent.

Sensors and Systems with IO-Link

IO-Link: The Intelligent Communication Technology

The first internationally standardized IO technology, IO-Link enables consistent, bidirectional communication between the control system and the lowest sensor/actuator level via standard, unshielded three-core cable—for both intelligent IO-Link and standard sensors. With this future-proof interface, users can perform comprehensive diagnostics or configure IO-Link devices during operation. Pepperl+Fuchs offers you an end-to-end IO-Link system solution that includes a range of IO-Link sensors and infrastructure.

Get your plant ready for the future. Benefit from reduced operation costs and transparent data exchange down to the field level.

Did you know that ...

Benefits

Increased Efficiency and Sustainable Cost Reduction

IO-Link Minimizes Downtime

Transparency Down to the Lowest Field Level

Features of IO-Link

Future-Proof Interface for Sensorik4.0® Applications

A Variety of Diagnostic Options Enable Efficient Maintenance

Reliable Localization Function Simplifies Maintenance

Data Storage Function Simplifies Sensor Replacement During Operation

A Complete IO-Link Solution

Pepperl+Fuchs offers a complete IO-Link system solution for your application. This enables consistent communication between IO-Link devices at the field level and higher-level systems at the management and control level. Not only are powerful field devices and software available, but also the corresponding infrastructure components.

IO-Link Infrastructure

Latest IO-Link Products

For users with a focus on implementing future-proof Industry 4.0 identification applications, the IQT3* HF read/write devices offer an ideal solution. These can be quickly and cost-effectively integrated into architectures such as PROFINET, EtherNet/IP, and EtherCAT via the built-in IO-Link interface in conjunction with an IO-Link master … more

Parameterization, Commissioning, Maintenance—How Does This Actually Work?

IO-Link configuration and integration is easy with uniform device description files, standardized IO Device Descriptions (IODDs), and parameter-setting with the help of software tools. With new transparency down to the field level, users can perform both comprehensive parameter setting and use the device’s diagnostic capabilities—the foundation for predictive maintenance.

IO-Link Commissioning Within the Automation System

IO-Link system configuration consists of several steps. First, the IO-Link master is integrated into the automation system and configured. Second, the device parameters are set using an IO-Link configuration tool, which displays the entire system architecture from the control system down to the field level.

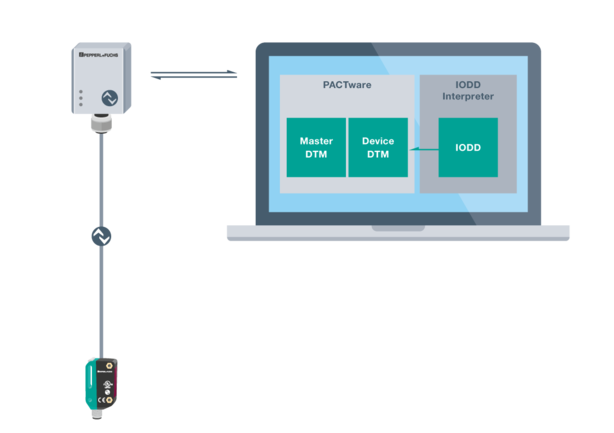

PACTware for Offline Parameterization of IO-Link Devices

With the help of the cross-vendor and cross-fieldbus operator software PACTware, IO-Link sensors are easy to configure and operate. In addition to the readily available IO Device Description, device-specific DTMs (device type manager) are available for IO-Link sensors. They enable convenient sensor operation through a graphic user interface.

The Standard for Future-Proof Technology

Simplified Device Replacement and Maintenance

Detecting which devices need maintenance can be difficult in applications with many similar sensors—like in conveyor systems. The localization function can be activated to find the sensor quickly and easily with the help of flashing LEDs. Once the device in need of maintenance is located, the integrated data storage function makes it possible to replace sensors during operation with no new parameterization required. This significantly reduces plant downtime.

Smart Sensor Profiles—The Next Step Towards Standardization

Even though there are a wide variety of IO-Link sensors currently available, like those offered by Pepperl+Fuchs, they share many functional similarities.

Smart Sensor Profiles unify common functions, settings, and their meanings in order for IO-Link sensors to be integrated faster and more flexibly than ever before.

Production in Batch Size 1—Parameterization During Operation

Recipe changes are often necessary when different products are made on a production line. With the simultaneous transfer of process and parameter data, IO-Link enables the reparameterization of sensors and actuators during operation—laying the groundwork for production in batch size 1. This reduces downtimes and resulting costs.

Contact Us

What advantages does IO-Link offer for my plant? How do I incorporate the technology into my existing communication system? We are happy to answer these and other questions. Just send us a message or arrange a personal consultation with one of our experts.

Downloads

Downloads

- Brochure: "Sensors and Systems with IO-Link" (PDF; 4,81 MB)

More Information

More Information

- IO-Link Technology Learn more about the intelligent communication technology.

- IO-Link Portfolio Get to know our comprehensive IO-Link portfolio.

- IO-Link Community Get information on IO-Link, its benefits and technical details.

- IODDfinder Database for Description Files Get access to a central crossvendor database of all description files, the IODDs, and an overview of all IO-Link devices.

- Finding a Common Denominator in IO-Link—Smart Sensor Profile Edition 2 Read how IO-Link sensors can be integrated faster and more flexibly than ever before.

+358 20 7861 290

+358 20 7861 290