Pharmaceutics

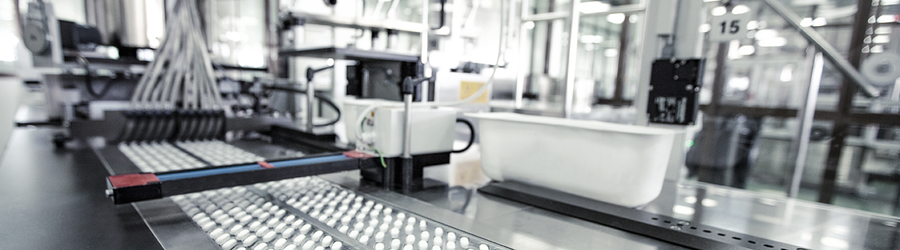

As a highly regulated sector, the pharmaceutical industry has to comply with a large number of laws and regulations. Companies not only have to ensure quality and purity for each individual production step, but also document it and reliably store the corresponding data. This is the reason why pharmaceutical companies benefit in particular from digitalization and automation.

As a trusted partner, Pepperl+Fuchs offers pharmaceutical companies a wide range of products that support complex production and quality assurance. These include GMP-compliant HMI systems and solutions that are precisely tailored to the diverse requirements of pharmaceutical production. As the individual process steps and operating locations pose varying challenges, Pepperl+Fuchs offers an end-to-end thin client portfolio and HMI systems that are suitable for highly regulated and hygienic conditions. This means that customers receive everything they need in terms of HMI systems from a single source.

Portfolio

The fully modular "One Fits All" design of the VisuNet FLX series enables precise configuration of HMI systems and solutions for pharmaceutical industry applications, available for ATEX/IECEx Zone 2/22 and Division 2, as well as for non-hazardous areas. The housings made of stainless steel with special surfaces easily comply with GMP regulations. They are particularly easy to clean and resistant to aggressive and corrosive substances. The stainless-steel version is available as a stand-alone HMI system or for panel mounting.

The VisuNet GXP series provides users with modular, field-maintainable HMI systems for life science applications up to Zone 1/21. With a continuous stainless-steel housing with no room for dust or liquid accumulation, VisuNet GXP components are resistant to all chemicals and detergents commonly found in the life sciences sector—and the GXP is the industry’s lightest remote monitor for Zone 1/21 life science applications.

In addition, Pepperl+Fuchs offers a wide range of peripheral devices for the operator stations. These include explosionproof handheld readers for material identification and tracking, integrated RFID readers for user authentication as well as antibacterial keyboards with a choice of touchpad, trackball, or joystick.

As the pharmaceutical industry itself, the requirements for HMI systems are diverse and cannot always be met exactly with standard products. In this case, Pepperl+Fuchs supports users with customized solutions. The experts at the Solution Engineering Centers (SECs) develop, manufacture, and certify individual solutions that are precisely tailored to the application. These include, for example, mobile operator stations, dual monitor stations, and operator stations for different mounting options such as wall or ceiling arm.

The industrial box thin clients (BTCs) from Pepperl+Fuchs are suitable for use in harsh industrial environments. With a robust aluminum housing, they can withstand demanding environmental conditions and are suitable for 24/7 operation. Therefore, the BTCs always provide reliable access to virtualized applications and information from central servers. The latest BTC supports up to four 4K video outputs at 60 Hz.

Pepperl+Fuchs offers not only the hardware for pharmaceutical production, but also the necessary software. The Windows® based VisuNet RM Shell firmware is preinstalled on every VisuNet remote monitor and box thin client. Using standard Ethernet technology, it allows access to both virtualized and conventional PC-based process control systems. The add-on tool VisuNet Control Center enables efficient, centralized configuration and remote maintenance of all RM Shell-based thin clients.

For users who prefer the Linux based IGEL operating system, Pepperl+Fuchs offers the VisuNet thin clients also with preinstalled IGEL OS.

When new medicines come onto the market that promise relief or even a cure for a large number of people, large quantities have to be produced quickly—in the highest quality and purity. In our amplify article, read how HMI systems support the personnel in the large-scale production of pharmaceuticals.

+49 621 776-0

+49 621 776-0