| General specifications |

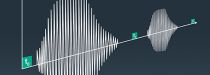

| Sensing range | 30 ... 300 mm |

| Adjustment range | 50 ... 300 mm |

| Dead band | 0 ... 30 mm |

| Standard target plate | 100 mm x 100 mm |

| Transducer frequency | approx. 380 kHz |

| Response delay | 21 ms minimum

63 ms factory setting |

| Indicators/operating means |

| LED green | solid: Power-on

flashing: Standby mode or program function object detected |

| LED yellow 1 | solid: switching state switch output 1

flashing: program function |

| LED yellow 2 | solid: switching state switch output 2

flashing: program function |

| LED red | solid: temperature/program plug not connected

flashing: fault or program function object not detected |

| Temperature/teach-in connector | Temperature compensation , Switch points programming , output function setting |

| Electrical specifications |

| Operating voltage | 10 ... 30 V DC , ripple 10 %SS |

| No-load supply current | ≤ 50 mA |

| Interface |

| Interface type | RS 232, 9600 Bit/s , no parity, 8 data bits, 1 stop bit |

| Input/Output |

| Synchronization | bi-directional

0 level -UB...+1 V

1 level: +4 V...+UB

input impedance: > 12 KOhm

synchronization pulse: ≥ 100 µs, synchronization interpulse period: ≥ 2 ms |

| Synchronization frequency | |

| Common mode operation | max. 95 Hz |

| Multiplex operation | ≤ 95 Hz / n , n = number of sensors , n ≤ 5

|

| Output |

| Output type | 2 switch outputs PNP, NO/NC, programmable |

| Rated operating current | 200 mA , short-circuit/overload protected |

| Voltage drop | ≤ 2.5 V |

| Repeat accuracy | ≤ 0.1 % of full-scale value |

| Switching frequency | ≤ 7 Hz |

| Range hysteresis | 1 % of the adjusted operating range (default settings), programmable |

| Temperature influence | ≤ 2 % from full-scale value (with temperature compensation)

≤ 0.2 %/K (without temperature compensation) |

| Compliance with standards and directives |

| Standard conformity | |

| Standards | EN IEC 60947-5-2:2020

IEC 60947-5-2:2019 |

| Approvals and certificates |

| UL approval | cULus Listed, General Purpose |

| CCC approval | CCC approval / marking not required for products rated ≤36 V |

| Ambient conditions |

| Ambient temperature | -25 ... 70 °C (-13 ... 158 °F) |

| Storage temperature | -40 ... 85 °C (-40 ... 185 °F) |

| Mechanical specifications |

| Connection type | Connector plug M12 x 1 , 5-pin |

| Degree of protection | sensor head: IP67

connector sensor head/controller unit: IP52 |

| Material | |

| Housing | stainless steel (1.4305 / AISI 303)

PBT plastic parts |

| Transducer | epoxy resin/hollow glass sphere mixture; polyurethane foam |

| Mass | 210 g |

| Dimensions | |

| Length | 25 mm |

| Diameter | 18 mm |

| Factory settings |

| Output 1 | Switching point: 60 mm

output function: Switch point operation mode

output behavior: NO contact |

| Output 2 | Switching point: 500 mm

output function: Switch point operation mode

output behavior: NO contact |

+49 621 776-0

+49 621 776-0