Ultrasound—but Different.

Ultrasonic Sensor System

USi®-industry

Ultrasonic Sensor System USi®-industry with Two Independent Sensor Channels

Outstanding Detection Abilities

Maximum Flexibility in Operation

Optimal Application Adaptation

Two Independent Transducers on a Single Evaluation Unit

Up to two ultrasonic transducers can be connected to the evaluation unit of the USi-industry ultrasonic sensor system. As they work completely independent of each other, various different applications can be solved with a single USi-industry sensor system. This outstanding adaptability is further enhanced by the fact that the evaluation unit can save two different parameter sets for each autonomous sensor channel—so the user has the option of triggering a change between both sets via the parameterizable digital input of the evaluation unit during operation.

In combination with the remote design of the transducers, which are available with cable lengths of up to three meters, the system can be used very efficiently in applications where left/right or forward/reverse movements in a space need to be monitored—on automated guided vehicles (AGV), for example. Due to its robust design and the exceptionally high degree of protection (IP69) of the transducers, the USi-industry system can also be used effectively for similar applications in outdoor areas.

Technology

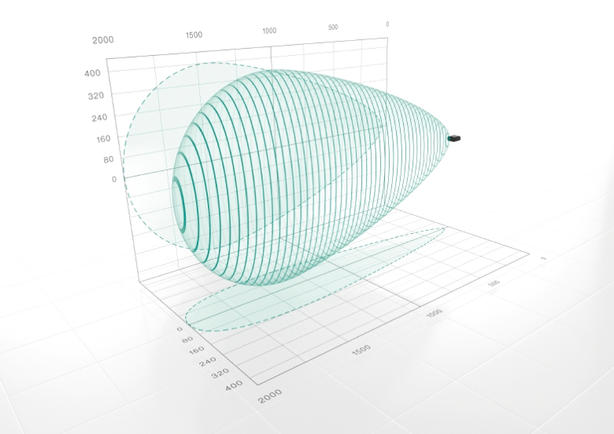

Elliptical Sound Field for Especially Wide Sensing Range

Whereas conventional ultrasonic sensors emit acoustic signals in the form of a radially symmetrical sound beam, the USi-industry uses a highly elliptical sound field. The opening angle of ± 17° / ± 5° creates an especially wide sensing range in one plane and a narrow sensing range in the other. This allows the transducer to be mounted in confined installation situations.

This means that the system can also be used successfully just above ground level or close to a wall. At the same time, this technology—which is optimized for capturing 3-D spaces—enables the sensor to detect switching targets as well as overhanging or ground-level obstalces.

The Components

Furthermore, the USi-industry system is not limited to the output of value-discrete signals: In addition to the standard version with four switching outputs, the evaluation unit is also available as a version with three switching outputs and a 4...20 mA or 0...10 V analog output for measuring applications.

The robust die-cast aluminum housing complies with degree of protection (IP65), making the evaluation unit also suitable for outdoor use. In addition to the connections for the ultrasonic transducers, there is a USB interface for convenient parameterization via PC.

The System

The USi-industry ultrasonic sensor system consists of an evaluation unit, up to two ultrasonic transducers, and the software. To learn more about the individual components, click through the tabber menu on the right.

Video

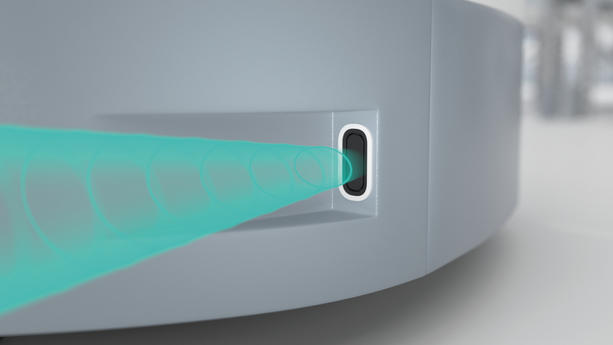

Miniature housing design, detached ultrasonic transducers, elliptical sound field—these features distinguish the USi-industry ultrasonic sensor system from other standard ultrasonic sensors.

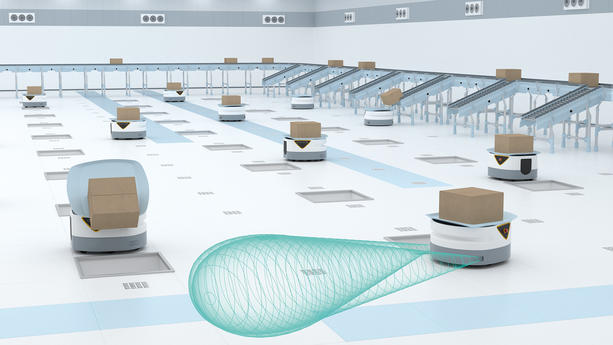

The USi-industry sensor system offers an excellent solution for implementing a gapless anti-collision system on AMRs: With its large 3D detection field, it can be used as a stand-alone sensor system, or in combination with other sensors used for AGV navigation by reliably monitoring blind areas in the vehicle’s periphery. Due to the integrated mutual interference suppression, several USi-industry sensor systems can be operated in parallel without interfering with each other. The small size of the ultrasonic transducers, which are detached from the evaluation unit, also favors both functional integration and harmonious integration into the vehicle design.

Application Examples

Anti-Collision System for AMRs

To ensure collision-free movement of AMR fleets (autonomous mobile robots) in warehouses, the individual vehicles must be extensively equipped with reliable sensors. This is the only way to react to changes and recalculate the route if obstacles or other AMRs are detected on the route. At the same time, it is important to ensure that the sensor signals of the individual AMRs do not interfere with each other.

As a key component of an anti-collision assistant, the USi-industry sensor system with its large 3-D detection field helps to minimize the risk of unintended collisions between the ground support equipment and the aircraft being loaded: The ultrasonic transducers mounted on the belt boom comply with degree of protection IP69, so that neither heavy rain nor high-pressure cleaning processes can penetrate the extremely compact transducer housing. Temperature compensation integrated into the evaluation unit ensures that daily or seasonal temperature fluctuations on the tarmac do not affect the reliability of the ultrasonic measurement results.

Anti-Collision System for Ground Support Equipment

Ground support equipment at airports, such as conveyor belt carts, is essential for smooth loading processes. However, due to the ever-present time pressure of aircraft handling or during poor weather and visibility conditions, there is a certain risk of collisions between the conveyor boom and the aircraft fuselage, which can lead to costly damage to the aircraft and delays in take-off.

You Might Also Be Interested In …

If you want to use the exceptional features of the USi-industry in safety applications up to Category 3 PL d, the award-winning USi-safety is the right choice for you. The USi-industry's sister system has two microcontrollers that monitor the connected sensors, its own hardware and each other for correct functioning. This ensures that the system is fail-safe in accordance with EN ISO 13849-1. In addition, both OSSD outputs are short-circuit and cross-circuit monitored.

Bízzon az ultrahangos érzékelők szakértőiben

Házon belüli, megbízható minőség

A Pepperl+Fuchs ultrahangos érzékelőit saját műszaki központunkban építjük, ahol a jelátalakító-fejlesztés és -gyártás zajlik. Előre gondolkodó szakértőkből álló csapatunk több mint 30 éve folyamatosan azon dolgozik, hogy a holnap megoldásai érdekében továbbfejlessze az ultrahangos technológiát. Ez azt jelenti, hogy ügyfeleink mindig a piacon elérthető legjobb teljesítményű termékekhez juthatnak hozzá.

Ez a megközelítés az iparág leggazdagabb portfólióját eredményezte – amelyet számos szabadalom és innováció támogat – a termékkiválasztás és az optimális alkalmazási megoldások legmagasabb fokú rugalmassága érdekében. Általános portfóliónk mellett a Pepperl+Fuchs rendelkezik a szükséges tudással és infrastruktúrával ahhoz, hogy gyorsan és rugalmasan tudjon reagálni az ügyfelek igényeire.

Sőt, a tartozékok széles választéka révén megfelelő részegységek alkalmazhatók a testreszabott integrációhoz, legyen szó nehéz telepítési körülményekről, speciális alkalmazásokról, egyedi programozásról vagy összehangolt csatlakozási technológiáról. Minden érzékelős alkalmazást nagy teljesítményű, időtálló rendszermegoldássá alakítanak.

Ultrahangos műszaki útmutatók – Ingyenes letöltés most!

Letölthető dokumentumainkban megosztjuk Önnel szakértelmünket – iratkozzon fel most, és kap egy ingyenes, digitális másolatot az ultrahangos érzékelőink műszaki útmutatóiról! Segítségükkel könnyedén kiválaszthatja az alkalmazásához legideálisabb érzékelőt, hogy a legtöbbet hozhassa ki berendezéséből.

Kapcsolat

More Information

More Information

- USi-industry Ultrasonic Sensor System (Datasheets)

- USi-safety Ultrasonic Sensor System (Datasheets)

Downloads

Downloads

+36 88 545 902

+36 88 545 902