LB remote I/O stations are mounted in Zone 2, Class I/Div. 2 hazardous areas. They form a modular signal conditioning system to interface signals from the field to a control system in the safe area. LB Remote I/O connects conventional sensors and actuators to the DCS using a single standardized fieldbus connection (PROFIBUS, Modbus, etc.).

A wide range of single- and multi-channel I/O modules is available—ensuring that engineering is easy and adaptable to the needs of your plant concept.

The 4-channel, universal input/output module with Ex i terminals is a highly flexible solution for applications such as operation of pressure transmitters, flow transmitters, differential pressure transmitters, level transmitters, and proportional valves, I/P converters, or local indicators. Each of the four channels can be independently parameterized and operated as either AI or AO.

Analog input modules not only power the connected transmitter, but also digitize the measured current for bus communication. Multiple transmitter power supplies can be used for connection of 3-wire transmitters up to 23 mA. The LB system remote I/O analog inputs are available in 1-channel and 4-channel versions with Ex i inputs.

Digital input modules process input signals from binary sensors or mechanical contacts from the field. The modules feature Ex i terminals and are ideally suited for connecting NAMUR proximity switches, optocouplers, or volt-free contacts. Digital inputs are available in 2-channel, 3- channel, or 8-channel versions.

Supplied with passive signals from NAMUR sensors, optocouplers, or volt-free contacts, the frequency input modules in our LB system remote I/O solution enable measurement of parameters and detection of rotational direction. Our frequency input models feature Ex i terminals are available in 1-channel versions.

Temperature measurement is one of the most safety-critical applications in process automation—especially in explosion-hazardous areas. These temperature input modules with Ex i terminals allow connection of different resistance thermometers (2-, 3- and 4-wire Pt100 ... Pt1000), thermocouples, and mV signals and are available in 1-channel and 4-channel versions.

Whether for control of proportional valves, positioners, actuators, local display units, or I/P converters—analog output modules from Pepperl+Fuchs LB system remote I/O solution are a fixture in process automation applications. They feature terminals in type of protection Ex i and are available in 1-channel and 4-channel versions.

For control of intrinsically-safe solenoid valves, LED clusters, beacons, horns, or other standard switching functions, Pepperl+Fuchs provides digital output modules, featuring terminals in type of protection Ex i. Digital outputs are available with different channel numbers to cover diverse application requirements.

Many applications include basic ON/OFF switching routines. Simple status and alarm indication is noted via beacons, flashlights, sirens, or horns. To control these indicators, solenoid valves, or other switching functions in Zone 2, Class I/Div.2 explosion hazardous areas, Pepperl+Fuchs provides relay outputs with Ex nA terminals. They are available in 4- and 8-channel versions.

This 24V remote I/O power supply module in type of protection Ex nA feeds the I/O modules and com units/gateways that are mounted on the corresponding backplane. The power supply features galvanic isolation to mains power and can be operated in redundancy mode.

For easy connection of I/O modules from LB system remote I/O solution to a DCS, SCADA system, or PLC, Pepperl+Fuchs offers com unit modules (gateways). These modules are available for different industrial communication protocols and connect the internal bus of the mounting backplane to the higher-level bus system.

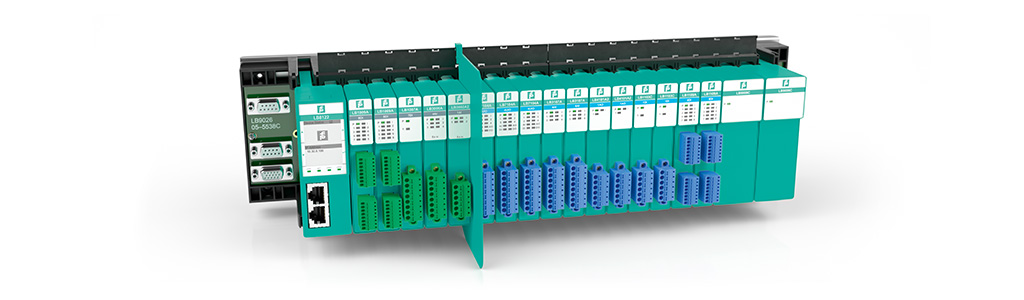

For mounting the various interface modules of the LB system remote I/O solution, Pepperl+Fuchs offers backplanes that are available with 8, 10, 12, 16, 22, or 24 single-width slots and can carry any combination of single-width and dual-width remote I/O modules.

Field units ensure protection of all electronic components from harsh ambient conditions. There are two types of enclosure materials available: enclosures made from lightweight glass fiber reinforced polyester and enclosures made from electropolished 316L stainless steel. Both enclosure types meet degree of protection IP66.

Pepperl+Fuchs offers a variety of accessories to enable custom-fit remote I/O installations. Various D-sub connectors and cables link the base and extension backplanes used for module mounting. Terminal blocks, protective covers for terminal blocks, cold junction blocks, and a watchdog plug are also part of the portfolio. The product range is rounded out by a separation wall that is used to maintain the 50 mm clearance between intrinsically safe and non-intrinsically safe circuits.

+91 80 4609 6000

+91 80 4609 6000