Driving Conveyor Technology.

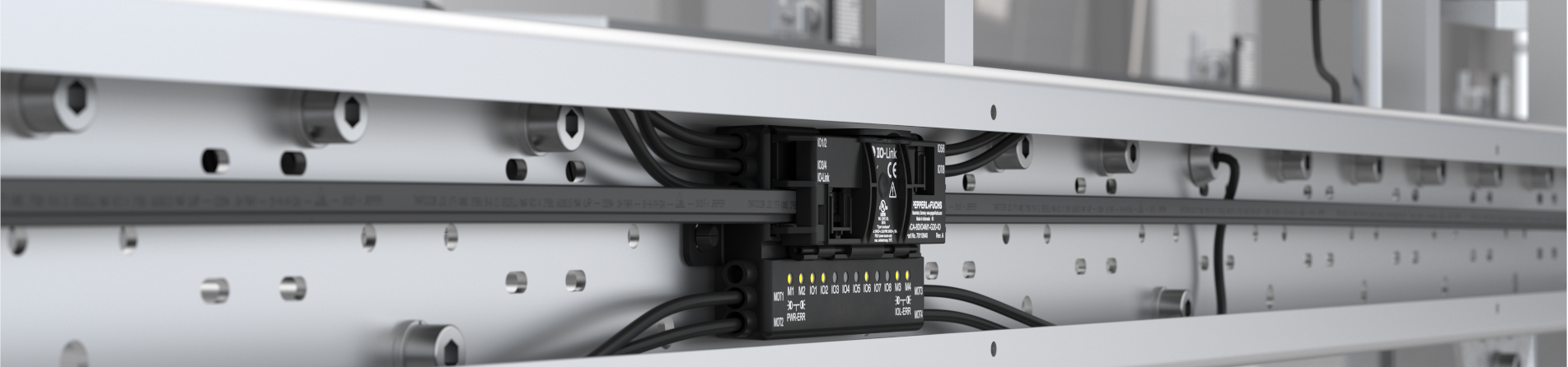

Unmatched housing advantages: perfected for seamless integration and easy installation.

G20 Series Motor Control Modules

The G20 control modules for MDRs have an application-optimized, slim design that allows direct installation in the mounting rail of the roller conveyor line. All connection cables for sensors and motorized rollers are already integrated in the module. The flat cable for communication and/or powering can easily be inserted in the last step.

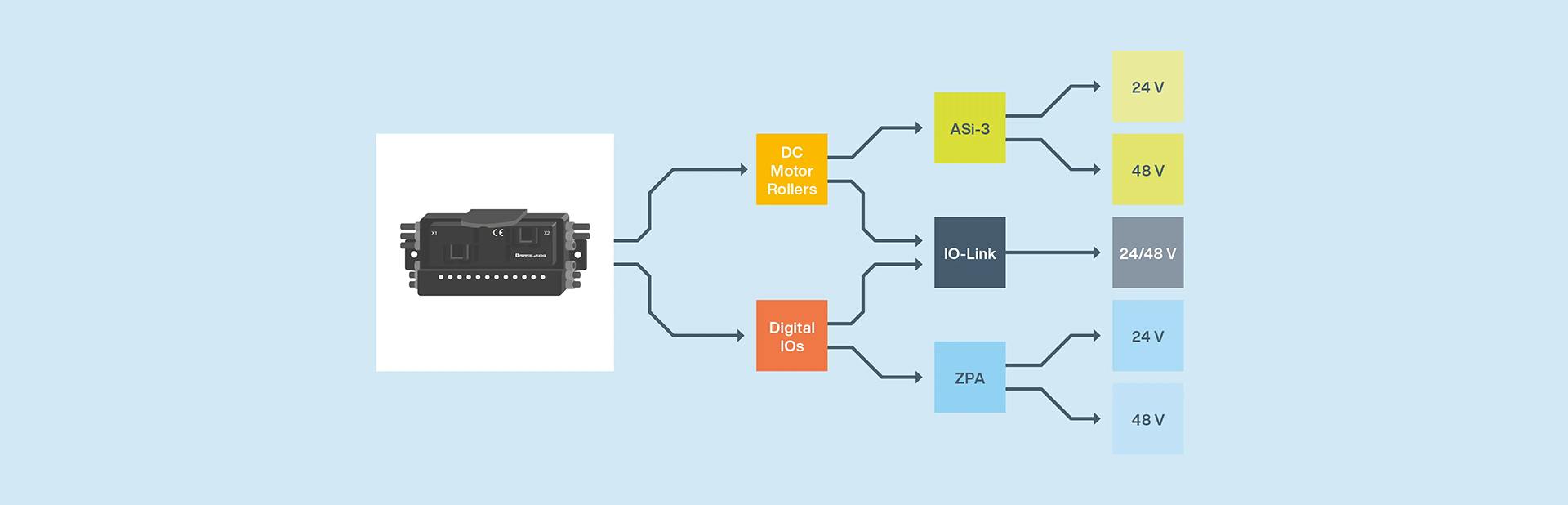

With the available communication protocols AS-Interface, IO-Link, and ZPA as well as the option of controlling either 24 V or 48 V motorized rollers, the G20 series offers maximum flexibility and efficiency in your conveyor technology application!

Benefits

Seamless Integration

Easy Handling

Increased Cost-Efficiency

G20 Series in Use

The compact motor control modules of the G20 series from Pepperl+Fuchs for controlling 24 V or 48 V DC motorized drive rollers impress with their unique housing concept. Due to their compact design, the G20 motor control modules can be installed directly in the mounting rail of a roller conveyor.

The G20 modules from Pepperl+Fuchs are available with different protocols such as AS-Interface or IO-Link, or as stand-alone ZPA units. This means that the optimum solution can be selected for every roller conveyor application.

Features of the G20 Series

Compact Housing Design

The housing of the G20 motor control modules is designed to be integrated into the mounting rail in a particularly space-saving manner.

Tool-Free Mounting Concept

All modules are equipped with a flat cable connection that enables tool-free installation using the piercing technology. Sensor and actuator cables are also integrated in the, allowing the conveyor line can be set up cost-effectively and without any special prior knowledge.

Pre-Assembly of Individual Conveyor Segments

You have the option of ordering individual conveyor segments pre-assembled together with all modules and settings. In the final step, the yellow flat cable and the sensors are integrated on site so that the system can be put back into operation immediately.

Using the Benefits of IO-Link

The G20 module with IO-Link makes most of its benefits at points with a high IO density, such as buffer zones, sorting points or intersections with elevators, where it ensures a reliable flow of goods. It collects up to eight digital signals and controls up to four motorized rollers simultaneously.

A Comparison of Technologies

View Products

View Products

View Products

The Optimum Solution for Every Application

The modules of the G20 series have the ability to control the start/stop functionality, the direction of rotation, the acceleration/deceleration,

and the speed of the motorized rollers within the conveyor system. Besides, they can also be used to collect digital IOs

allowing system operators to choose the solution that fits best for their specific use case.

The Right Solution for Your Conveyor System Application

With Pepperl+Fuchs as your partner in the field of industrial communication, you receive a comprehensive all-round solution for conveyor systems. In addition to the various G20 modules for controlling DC motorized rollers, we offer you the right infrastructure for setting up flexible and cost-efficient conveyor lines. In addition to the constantly growing AS-Interface and IO-Link portfolio, we are already working on further interfaces that will enable system planners to configure individual solutions for their conveyor systems in the future using a modular principle.

Supported Motor Roller Manufacturers

- Interroll

- Itoh Denki

- Pulseroller

- Rulmeca

- Unidrive

- Winroller

The motor rollers you are using is not listed? Please feel free to concact us and see whether we can do an engineering for your system and set up and individual solution for your application.

お問い合わせ

Are you looking for a suitable solution for your conveyor application and would like to find out more about the various modules in the G20 series for controlling motorized rollers? We will be happy to help you. Simply fill out the contact form and send us a message.

Downloads

Downloads More Information

More Information

+81 45 6249077

+81 45 6249077