Easy Control of Refuse Collection Vehicles with Ultrasonic Sensors

Ultrasonic sensors allow safe mobile equipment operations

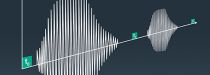

Ultrasonic sensors from the 30GM70 Series control the fill level on the inside of vehicles

18GM40 Series detects the size of the refuse containers

L2 Series for safeguarding lifting and tipping operations

30GM70 Series monitors the contents of the vehicle

The ultrasonic sensors help to ensure fault-free and virtually automatic operation

Your benefits at a glance

- Safeguarding the lifting and set-down area for the refuse container

- Efficient and fault-free emptying sequence without the need for manual intervention

- Automatic container size detection

- Overflow monitoring of the feed area on the vehicle

PDF Downloads: Technology Guides Ultrasonic Sensors

Pepperl+Fuchs offers you various downloadable documents containing knowledge on ultrasonic sensors. In addition to a general technology guide on ultrasonic sensors, you can now download a new guide focusing on double material detection with ultrasonic sensors. Get your free PDF documents and benefit from valuable insights and advice for your field work!

+49 621 776-0

+49 621 776-0