Reliable Positioning of Stacker Cranes in High-Bay Warehouses with the PXV

PXV Absolute Positioning System in Warehousing and Material Handling

The Application

Automated high-bay warehouses with stacker cranes have become indispensable in warehousing, material handling, and distribution centers. The automated systems store and retrieve items particularly efficiently. Compact dimensions, high speeds, and increased picking accuracy are just some of the many benefits of this technology.

The Goal

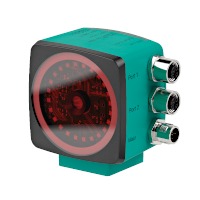

PXV absolute positioning system

To ensure high throughput and avoid downtime costs, the stacker crane must be positioned with reliable precision and at high speed. A reliable absolute positioning system is therefore crucial for operation. In addition to having a quick reaction time, this system must provide position data down to the submillimeter.

The Solution

The absolute positioning system PXV, consisting of a read head and Data Matrix code tape, offers the perfect solution. Measuring just 25 mm in width, the code tape is narrow enough to be installed directly in the shaft of the stacker crane. The 2-D camera is located on the moving carrier. This installation procedure is carried out on the stacker crane’s horizontal and vertical axis. The sensor immediately provides a reliable X- and/or Y-axis position in order to precisely position the stacker crane for storage or retrieval. The position resolution of 0.2 mm and the travel speed of up to 20 m/s make the PXV technology not only highly accurate, but also quick enough to meet the requirements of the control system. While other technologies require calibration and maintenance intervals, neither are necessary in this system because there are no moving parts.

Technical Features:

- +/– 0.2 mm precise measurement resolution up to a track length of 100 km

- Interfaces: RS485, SSI, EtherNet/IP, or PROFINET

- Travel speed: up to 20 m/s

- Easy-to-install Data Matrix code tape

- Noncontact and maintenance-free

- Safe version safePXV with SIL 3/PL e

The Advantages

In addition to being highly reliable and accurate over long distances, the PXV system is easy to install and set up. This system does not incur any consequential costs and it can be replaced quickly in case of a fault. If the stacker crane is used in a high-bay warehouse where the items are stored especially high up and safe positioning (redundant position) is needed, the safe version safePVX with PROFIsafe and SIL 3/PL e is available.

At a Glance

- The best and most reliable absolute positioning system: unique combination of 2-D camera and Data Matrix code tape

- Highly flexible: Noncontact positioning up to 100,000 m

- Total reliability due to multiple code redundancy even with dirt or some damaged codes – one readable code required

- Quick installation using adhesive code tape: no need for exact camera orientation due to wide reading window and large depth of field

+46 303 246070

+46 303 246070