Powered by Expertise.

With passion for technology and decades of know-how in the processes of the automotive industry.

Sensors and Automation Solutions for Battery Production

Whether as the heart of electric vehicles or as a storage medium for electricity from renewable energies: The battery plays a central role in the mobility and energy supply of the future.

Powerful sensors and automation solutions are required to ensure the highest quality and smooth processes in battery manufacturing. Pepperl+Fuchs offers a complete portfolio ranging from individual sensors to turnkey system solutions. This allows all process steps to be optimized—from the battery cells and modules to the battery pack and installation in the vehicle body. With decades of experience in automation technology, individual consulting, and the expertise of highly specialized subsidiaries, we support you in successfully automating your plant.

Discover our sensors and automation solutions for battery manufacturing!

Highlights

The Battery—in Focus in Various Industries

Whether for e-mobility, for the storage of electricity from renewable energies or for the electronics industry, the battery plays a central role in various industries worldwide.

The battery is the heart and currently the most expensive component of an electric car—which is why its production requires the highest quality and efficient processes. This is ensured by the appropriate sensor technology from Pepperl+Fuchs. A comprehensive portfolio is also available for many other processes related to the production of electric vehicles.

Learn more

Powerful batteries are needed to store climate-neutral electricity from wind power or photovoltaic plants. The demand for battery storage is therefore continuously increasing—both for network operators and in private households. With sensor technology from Pepperl+Fuchs, the required battery storage systems can be manufactured with particular efficiency. Pepperl+Fuchs also offers a wide range of compatible sensor solutions for other tasks related to solar and wind power plants.

Learn more

Battery manufacturing is one of the major growth areas in the global electronics industry. Many other processes in the electronics industry can also be automated with industrial sensor technology from Pepperl+Fuchs—from photovoltaic production to PCB processing.

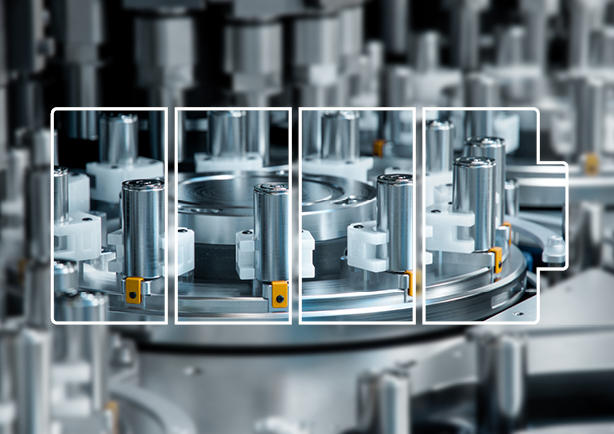

Learn moreBattery Cell Manufacturing

In the manufacture of battery cells, anode and cathode foils are stacked alternately, each separated by a separator foil. In this process, the need for monitoring in the calendering machine is high. Double feeding of foils, a web break or insufficient web tension quickly lead to production errors or machine downtimes. To prevent this, Pepperl+Fuchs offers suitable sensors that can be easily connected to the controller and the cloud via IO-Link.

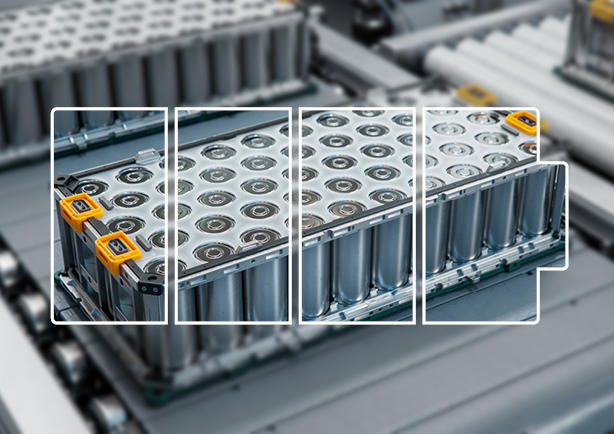

Battery Module Manufacturing

After battery cell manufacturing is complete, the individual battery cells are assembled into battery modules. To monitor this process, Pepperl+Fuchs industrial vision products are used. Vision sensors identify the battery cells and verify their correct number and orientation, while an industrial event camera monitors the entire manufacturing process.

More Solutions

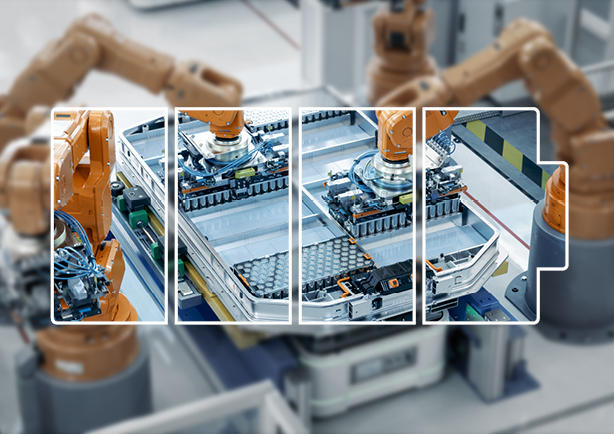

Battery Pack Manufacturing

Several modules are finally bundled to form a battery pack, which can be installed in the vehicle. Various systems and solutions from Pepperl+Fuchs are used in battery pack manufacturing—for example, for the precise correction of robot trajectories or for sustainable corrosion prevention.

Videolarda Daha Fazlasını Keşfedin

Akıllı Otomasyon Çözümleri

Bu video, akü modülü incelemesi ve izlenebilirlikten akü paketi üretimine kadar, üretim sürecinize yönelik çeşitli sensör çözümleri hakkında size bilgi verir. Örneğin, görüntü sensörü SmartRunner Explorer 3-D, akü modülünün yüksek çözünürlüklü bir 3 boyutlu nokta bulutunu oluşturur. Bu veriler, tam otomatik kalite kontrolü sağlayan model tanıma algoritmaları kullanılarak analiz edilebilir.

Akü Üretimine Yönelik Özelleştirilmiş Çözümler

Mevcut Pepperl+Fuchs portföyünde bulunmayan bir gereksiniminiz mi var? Modifiye edilmiş standart ürünlerden mevcut teknolojilere dayalı yeni geliştirilen ürünlere kadar özel uygulamalarınıza yönelik özelleştirilmiş çözümler geliştiriyoruz. Bireysel danışmanlık ve otomasyon teknolojisindeki onlarca yıllık deneyimimizle, akü üretim uygulamalarınız için doğru çözümü buluruz.

+90 216 577 2250

+90 216 577 2250