Hydrogen Production

On Earth, hydrogen only occurs in combination with other elements. One of the best known and most common compounds is the compound with oxygen in the form of water. In order to produce green hydrogen, water is split into hydrogen and oxygen molecules in an electrolysis process using electricity from renewable energies. This is done, for example, with proton exchange membranes (PEMs). These are located in so-called PEM cells, which consist of different layers: cathode and anode enclose the membrane and are each provided with catalyst layers. Together, these layers form the membrane electrode assembly (MEA). Together with a gas diffusion layer on both sides and two bipolar plates (BPP), they form a PEM electrolysis cell. To achieve the highest possible yields in the industrial production of hydrogen, several such cells are stacked here.

A PEM electrolysis cell consists of multiple layers.

Automated Production of PEM Cells and PEM Stacks

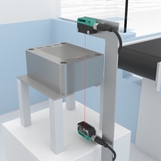

The assembly of the individual layers of a PEM stack has so far mostly been done manually and is time-consuming. In order to be able to produce large quantities efficiently and economically, increasing automation of stack production is required. For example, robotic arms can stack the layers of a PEM electrolysis cell and alternately place MEA and BPP on top of each other. To ensure that no errors occur here, various products from Pepperl+Fuchs are suitable for supporting automated production.

Innovative sensor technology supports automated PEM stack production.

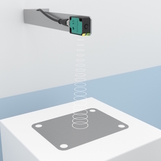

When producing PEM cells and stacks, care must be taken to ensure that no layer is placed on top of each other twice. If two MEAs are accidentally placed on top of each other, the PEM cell is not functional and the stack is unusable. To avoid this, double sheet sensors from Pepperl+Fuchs are used. They are able to recognize multiple layers by detecting boundary layers, i.e. the transition to an air gap. In this way, they guarantee that the robot arm only picks up one MEA at a time and does not accidentally pick up two.

Double layers of bipolar plates must also be avoided when producing PEM cells. The high-precision ultrasonic sensors of the F77 series can help detect such double layers. By measuring the distance to the underlying plate with an accuracy of 0.2 mm, they can infer the height of the plate and consequently detect whether two BPPs are accidentally on top of each other.

The stacking of the various layers of PEM cells must be very precise. Here, thru-beam photoelectric sensors from Pepperl+Fuchs can assist with the exact positioning of the layers. They are able to detect edges with high precision and can therefore reliably detect possible protruding layers.

Communication via IO-Link

The innovative sensors from Pepperl+Fuchs for automated PEM stack production feature standardized IO-Link interfaces. This allows users not only to make and change settings, but also query status data. The associated IO-Link masters transmit this data to higher-level systems via OPC UA so that it can be used, for example, for analyses and simulations. The sensors used therefore meet all the requirements of modern production in the sense of Industry 4.0.

+45 7010 4210

+45 7010 4210