Transporting Printed Circuit Boards

PCB detection using ultrasonic sensors

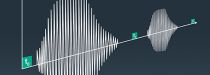

The F77 direct detection sensor features a wide projection cone to generate a measuring range of 20 mm...250 mm, allowing reliable detection of the PCBs as they pass

Small ultrasonic sensor with a big projection cone

The F77 direct detection sensor features a wide projection cone to generate a measuring range of 20 mm...250 mm, allowing reliable detection of the PCBs as they pass. The PCBs should enter the projection cone of the ultrasonic sensor at as perpendicular an angle as possible to ensure reliable reflection of the sound waves. A suitable distance between the PCB and the sensor must be calculated to eliminate the risk of raised components on the PCB falling in the sensor blind zone. Projection cone spread must be accounted for if the measuring distance is enlarged.

Ultrasonic technology for even greater reliability

Ultrasonic sensors provide a dependable switching signal even when faced with reflective surfaces, which are actually excellent reflectors of sound waves. Recesses in PCBs are rendered insignificant due to the width of the sound beam. Harnessing ultrasonic technology within the new miniature design offers a combination of significant benefits.

Interference- and maintenance-free system operation

The ultrasonic sensor continues to deliver reliable switching signals and superb background suppression even in the face of PCBs with recesses and reflective surfaces

Your advantages at a glance

- Very small design with tiny blind zone for cramped mounting conditions

- Easy installation and commissioning

- Reliable detection of reflective objects, regardless of the material

- High immunity to compressed air and plant noise

- Interference- and maintenance-free system operation

- Compatible with the housing of photoelectric models with a high switching frequency

PDF Downloads: Technology Guides Ultrasonic Sensors

Pepperl+Fuchs offers you various downloadable documents containing knowledge on ultrasonic sensors. In addition to a general technology guide on ultrasonic sensors, you can now download a new guide focusing on double material detection with ultrasonic sensors. Get your free PDF documents and benefit from valuable insights and advice for your field work!

+358 20 7861 290

+358 20 7861 290