Flexible Automatic Code Reading on Electronic Components with the VOS Ident

VOS-I with a Comprehensive Range of Accessories for Universal Use

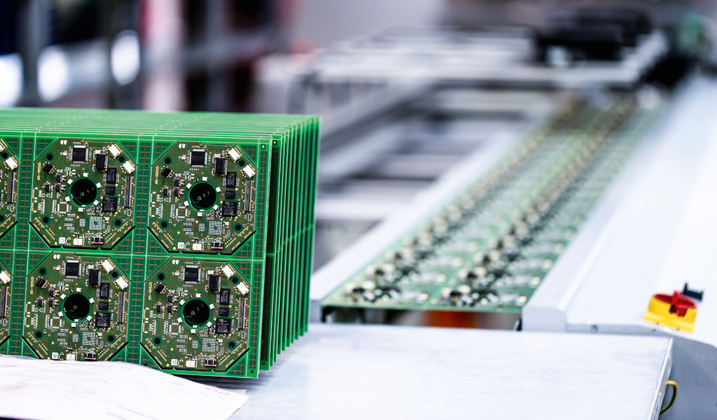

The Application

In the electronics industry, components such as printed circuit boards must be able to be identified reliably. This information is required both for controlling the production process and for complete traceability. As a general rule, the identifying information can be found directly on the PCB as a Data Matrix code. The code is either printed on a label or inscribed directly into the circuit board using a laser, which occasionally results in low optical contrast. The codes may also be placed on the side edge of the PCB and can be very small—up to a module size of 0.1 mm.

The Goal

Code reading must be able to cope with various requirements. Extremely small codes need to be read reliably, and it should be possible to read several codes at the same time, such as in the case of PCB trays. When reading a code following SMD assembly, information about the position of the code may also be required. For example, this can enable the absence of printed circuit boards to be assigned to a specific tray position. The code information must be relayed to the controller in a suitable format. When connecting to an ERP system, a data format that does not require any adaptation on the ERP side needs to be used. Furthermore, if there is a read error when reading a code, an error image must be available and easy to retrieve.

The Solution

VOS-I 2-D vision sensor

The VOS-I 2-D vision sensor reads all common 1-D and 2-D codes. It also features special decoders for reading laser-inscribed codes. The VOS-I has a wide sensing range and can read up to 64 codes simultaneously. The sensor area can be divided into several reading windows. This allows the code position to be output individually for each code.

Electronic filters compensate for difficult optical conditions using magnification and contrast enhancement, for example. The code quality can also be checked during DPM code reading based on ISO/IEC TR 29158 (AIM DPM). In the event of significant deterioration, the reading process can be interrupted and corrected. The device features all relevant fieldbus interfaces required for connecting communication cables. The output string can be configured for use with ERP systems to prevent an often time-consuming adaptation on the ERP side.

Technical Features

- Reading of all 1-D and 2-D codes

- Speed of movement up to 4 m/s

- Up to 30 readings per second

- Wide sensing range, distances of up to 2 m

- Resolutions of up to 5.2 megapixels

- Interfaces: TCP/IP, PROFINET, EtherNet/IP, RS-232, and I/O

- Storage of up to 32 jobs on the sensor

- Match code, multi-code, multi-window, and multi-sensor mode

- Output string formatting

The Benefits

The VOS-I series includes versions with a variety of different resolutions, as well as distance and sensing ranges. The series features devices with built-in lighting and lenses, alongside devices with C-mount connections that can be flexibly combined with various lenses and external lighting units. The VOS5000-I version featuring 5.2 megapixels is especially suitable for larger PCB trays. The sensing range can also be extended by using client-server networking to link several VOS-I devices.

At a Glance

- Reading of all common 1-D and 2-D codes including DPM (laser inscribed, needle punched)

- Multi-code reading of up to 64 codes in a single pass

- Recording of the position and quality of individual codes

- Optical filters to compensate for difficult optical conditions

- Wide selection of lighting and lenses

- All relevant interfaces are integrated, allowing for end-to-end communication all the way through to the ERP system

+358 20 7861 290

+358 20 7861 290