Cornering Angles, Inclination, and Acceleration for AGV Control

Dynamic Position Detection with Precise Inertial Measurement Unit

The Application

Automated guided vehicles (AGVs) are increasingly shaping the image of production and warehouse logistics. They handle the transport of parts and products between the various stations and processing areas. Their precise navigation is a prerequisite for smooth processes. As a rule, several sensors are used for this purpose per vehicle, in particular so that exact position detection is always available for cornering and evasive maneuvers.

The Goal

The transport materials should reach their target as quickly as possible; the target needs to be found and reached reliably. When navigating the transport route, flexibility is required to be able to react to obstacles and changes in the environment. The AGV has to be able to precisely stay in the track specified by the controller when driving in a straight line or cornering. This requires the sensors to accurately self-monitor the vehicle position.

The Solution

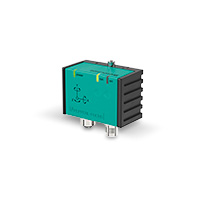

Inertial Measurement Unit F99

Optical sensors are normally used for general navigation in the environment. However, the AGV requires additional data to precisely determine its position at all times. Aligning two systems offsets measuring tolerances and small deviations. The inertial measurement unit F99 detects any deviation from the straight-line movement with high accuracy by measuring the Coriolis force with a capacitive MEMS sensor. It outputs the rotation rate values (°/sec) of the corners driven by the vehicle, thereby providing the additional data required for dynamic position detection and precise navigation.

Technical Features

- Inclination, acceleration, and rotation rate measurement along three axes

- IP68/69 degree of protection

- Parameterizable via interface

- Output formats and values can be selected

- Suitable for dynamic applications

- CAN bus with SAE J1939 protocol

- Increased EMC resistance

The Benefits

In addition to the rotation rate, the IMU F99 also supplies an inclination value for detecting the horizontal position of the vehicle in space, as well as acceleration values in three axes. These values serve as a further source of information for the AGV controller. A defined maximum steering angle value can be used to prevent the vehicle from tipping over when cornering. A sophisticated mounting concept offers great flexibility when placing the sensor in the AGV. With its rugged housing and IP68/69 degree of protection, it is suitable for use outdoors and in harsh environments. The rotation rate is measured without contact and without a target. The device does not need a mechanical axis of rotation or any ball bearings, making it maintenance-free for a long time.

At a Glance

- Precise angle values of cornering using capacitive measurement of the Coriolis force

- Exact inclination value to detect the horizontal position of the vehicle in the room

- Accurate acceleration values in three axes

- Noncontact measurement of the rotation rate without target and without mechanical wear

- Rugged housing and high degree of protection for use outdoors and in harsh environments

+49 621 776-0

+49 621 776-0