Absolute rotary encoders output a uniquely coded position value for each position. This means that no reference runs are required—neither when the machine is switched on nor after a supply voltage failure.

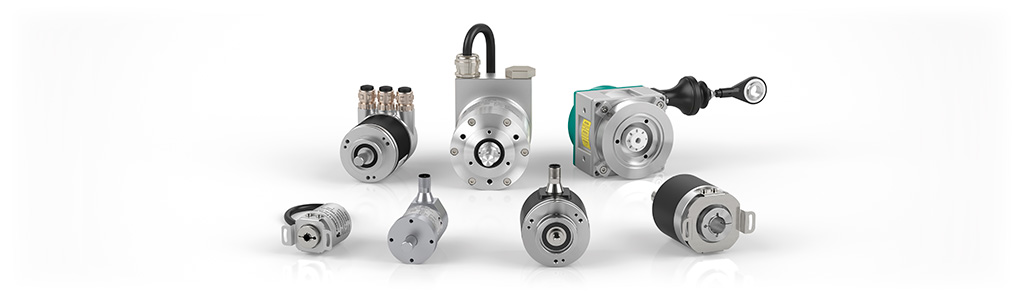

Pepperl+Fuchs offers a wide portfolio of singleturn and multiturn absolute rotary encoders. With singleturn absolute rotary encoders, the encoding starts again at the start value after each full revolution. Multiturn absolute rotary encoders additionally record the number of revolutions. The portfolio includes numerous variants—from cost-efficient sensors for standard applications to heavy-duty versions and rotary encoders for hazardous areas. Customized solutions can also be implemented for individual requirements.

For easy integration, Pepperl+Fuchs absolute rotary encoders are available with all common interfaces:

- PROFINET IO

- EtherNet/IP

- IO-Link

- PROFIBUS

- CANopen

- DeviceNet

- AS-Interface

- SSI interface

- Parallel interface

Heavy-Duty Absolute Rotary Encoders

Constant shock and vibration, high bearing loads, dirt and temperature fluctuations—the heavy-duty absolute rotary encoders from Pepperl+Fuchs are ideally suited for extreme environments. On cranes, excavators or lifting systems, the compact sensors impress with maximum reliability, even under the most adverse conditions.

Absolute Rotary Encoders for Hazardous Areas

Pepperl+Fuchs offers a range of absolute rotary encoders designed for gas and dust hazardous areas as well as for firedamp-sensitive mines. Due to ATEX and IECEx approvals, the sensors can be used worldwide up to Zone 1/21. In addition to compact versions for confined installation spaces, particularly robust variants are available for extreme environmental conditions.

+49 621 776-0

+49 621 776-0