ABB 800xA with ADM Integration - Download!

FieldConnex Advanced Diagnostics

ABB’s Control System 800xA pays special attention to the human operator. The 800xA platform provides the environment necessary to achieve operational excellence. Fitting ABB’s 800xA control system with physical layer diagnostics is easy. The ADM integration package for ABB provides the tools to tightly integrate FieldConnex® Advanced Diagnostic Modules into the ABB system.

In combination with FieldConnex® Advanced Diagnostics, 800xA Operations turns into a fully featured platform for managing the physical layer of a FOUNDATION fieldbus H1 infrastructure. Advanced Diagnostics offers a wealth of benefits from speeding up segment commissioning to providing early stage failure detection to support proactive maintenance strategies.

FieldConnex® is enabling technology

FieldConnex® Advanced Diagnostic Modules (ADM) plug into the FieldConnex® Power Hub. They monitor the fieldbus physical layer and communicate via the FieldConnex® Diagnostic Gateway with the FieldConnex® Diagnostic Server (FDS).

The FDS is a server application designed to allow the DCS to access data from the ADM modules. Such information is displayed and managed via the FieldConnex® Diagnostic Manager.

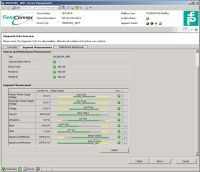

Hassle-free automated configuration

In ABB’s 800x system, alarms regarding the installation arrive in easy to understand fault descriptions, and include suggestions to correct them.

The ADM Project Builder ABB is a special software tool used for seamless integration of the ADM signals into the ABB control system. It reads the engineering data and automatically generates ADM and FDS configurations. Tags for ADM warnings and alarms are written back to the control system's configuration database. As a result, the fieldbus physical layer appears as a manageable asset within the control system environment.

FieldConnex® accelerated segment commissioning

Commissioning of fieldbus segments takes a few mouse clicks. All instruments are verified to be online and communicating. The loop check is done quickly – all from the safety of the control room.

While commissioning a fieldbus segment, the commissioning wizard automatically tests the physical layer by measuring key values for all devices. Automated tag reading enables the DCS to read and document tags. In this way, segment communication and verification only requires a few mouse clicks. Time consuming repetitive tasks are eliminated and the required time for segment commissioning is reduced by up to 80 %.

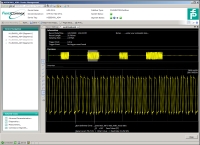

Expert system for fast troubleshooting

For fieldbus experts: The embedded oscilloscope provides detailed insights

Using the FieldConnex® Advanced Diagnostic Manager, the control system now includes a comprehensive expert system. The physical fieldbus layer is continuously diagnosed by comparing actual values against those set during commissioning. As soon as any potentially critical situation is detected, the system issues a warning. It also provides actionable incident-related information based upon past experience.

Due to the combination of measured values, configuration data, and experience-based information, the field technician already knows what needs to be done before arriving on site. Time needed for troubleshooting is reduced to an absolute minimum. Plant shutdowns are avoided.

The ADM Integration Package – ABB includes all required software. After the configuration of the DCS is complete, the project builder reads all configuration and segment tagging, and writes back configuration information for Advanced Diagnostics. With a few simple mouse clicks the setup is complete.

- Ask an Expert

- Cross Reference Request

- Check order status

- News

- NetPartner Login

- Subscribe to Gate-Way, our Process Automation Division e-newsletter

- Service Level Agreements for ecom instruments

- Find a Local Distributor or Representative

- Literature

- Technologies

- Control System Solutions

- Download Technical Documents

- Press Releases

- International Trade Shows

+1 330 425-3555

+1 330 425-3555