Bottle Counting on Drink Filling Machines With Ultrasonic Sensors

Ultrasonic sensors ensure reliable material flow

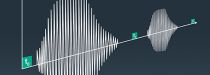

Through-beam ultrasonic barriers are particularly suitable for bottle counting

Speed and cleanliness are the determining factors in the food and beverage industry. Short cycle times and minimum machine and plant downtimes are of particular importance, while hygiene requirements must not be ignored. The strictest regulations and certifications are necessary in order to create high-quality end products.

In beverage filling systems, incoming and outgoing bottles must be continuously counted regardless of the material and type of liquid. At the outlets of PET bottle blowing machines and bottle washing machines, individual bottles are detected in order to ensure material flow.

Ultrasonic thru-beam sensors with a high degree of chemical resistance

Individual detection of conveyed bottles is normally too fast for sensing by ultrasonic sensors. The bottles pass the sensor too quickly and the gaps between the bottles are often too small. For this reason, ultrasonic thru-beam sensors are particularly suitable for bottle counting.

The use of hot steam and chemicals for machine cleaning in these applications requires ultrasonic thru-beam sensors with a high degree of chemical resistance. The IP degree of protection should be at least IP68/69K. The UBEC300-18GM40-... (splash zone) series is particularly suitable.

In machine areas not affected by cleaning cycles, it is possible to use standard ultrasonic thru-beam sensors such as the UBE1000-18GM40-... Series. Because the ultrasonic sensors from Pepperl+Fuchs recognize even the most difficult materials, transparent glass or plastic bottles are reliably detected.

Detecting and counting the bottles at several points in the machine ensures the continuous monitoring of material flow. The entry and exit of bottles in the filling system is optimized and missing bottles in the chain are reliably detected. Even in areas with strong steam generation, reliable detection of bottles is guaranteed with ultrasonic thru-beam sensors.

Detecting and counting the bottles at several points in the machine ensures the continuous monitoring of material flow

Your advantages at a glance

- Continuous monitoring of material flow

- Optimization of cycle times

- Detection of even the most difficult materials such as glass or transparent plastic bottles

- Ideal for high-speed applications

PDF Downloads: Technology Guides Ultrasonic Sensors

Pepperl+Fuchs offers you various downloadable documents containing knowledge on ultrasonic sensors. In addition to a general technology guide on ultrasonic sensors, you can now download a new guide focusing on double material detection with ultrasonic sensors. Get your free PDF documents and benefit from valuable insights and advice for your field work!

+1 330 425-3555

+1 330 425-3555