Space Efficiency for Enclosures in Ex and Non-Ex Areas

K-DUCT Profile Rail with Integrated Cable Duct Optimizes Installation

The Application

Control rooms and switch cabinets play a central role in process automation. The isolator modules installed there ensure galvanic isolation in the signal path between the field instrumentation and the control system. In explosion-hazardous areas, they are designed as isolated barriers, providing intrinsic safety for explosion protection. The number of components required in the cabinets increases with the size of the system and the degree of automation.

The Goal

Setting up control cabinets is complex and costly. The available space must be used as efficiently as possible. The accommodation of the numerous cables plays an important role here. The aim is to maximize the packing density with optimum cable routing in order to achieve the highest possible number of signals per enclosure or rack area.

The Solution

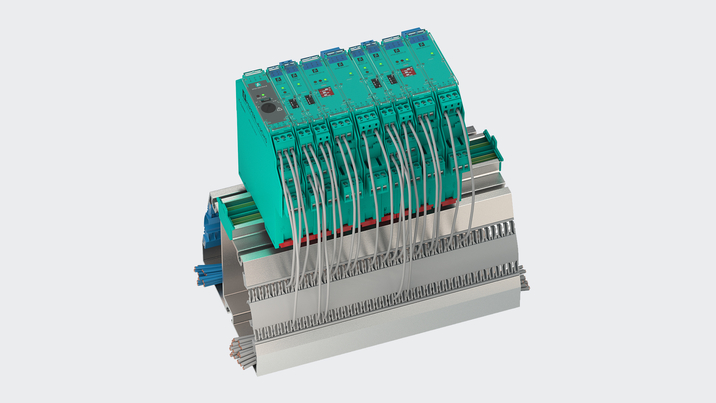

Increased packing density with K-DUCT series profile rails

In K-DUCT series profile rails, the cable ducts are located behind the DIN rail. Input and output wiring are separated by an integrated partition, which guarantees the spatial separation of Ex and non-Ex signals. No space is required above or outside the DIN rail for the cabling, which is accommodated with optimum use of the available space. Compared to conventional cable routing, the use of the K-DUCT system increases the packing density per enclosure by 50 percent. The K-DUCT series includes product versions for hazardous and nonhazardous areas. In conjunction with K-System modules, the profile rail can be installed in Zone 2/Div. 2 areas. Intrinsically safe signals are also permitted as field signals.

Technical Features

- Profile rail made of aluminum

- Plastic wiring combs for clean wiring separation

- Dimensions 130 × 113.2 × 1800 mm, can bereduced as required

- Weight approx. 6.5 kg

- Mounting hardware included

The Benefits

The optimal use of space significantly reduces installation costs. As only the input and output cables are required, the installation effort for the cable ducts is greatly reduced. The DIN rail of the K-DUCT series is equipped with our universal power rail that supplies Pepperl+Fuchs components directly with power and transmits error signals to the controller. The modules can be easily mounted and secured to the power rail. Components from other manufacturers can also be connected using standard wiring. The asymmetrically divided wiring space can be optimally located by rotating the profile rail.

At a Glance

- Highest packing density through optimal use of space

- Significant reduction in installation costs and assembly effort

- Cable duct integrated in the mounting profile

- Safe spatial separation of Ex and non-Ex signals

- No additional cable ducts required

- Ask an Expert

- Cross Reference Request

- Check order status

- News

- NetPartner Login

- Subscribe to Gate-Way, our Process Automation Division e-newsletter

- Service Level Agreements for ecom instruments

- Find a Local Distributor or Representative

- Literature

- Technologies

- Control System Solutions

- Download Technical Documents

- Press Releases

- International Trade Shows

+1 330 425-3555

+1 330 425-3555