Maximum Precision on the Smallest Scale

Miniature photoelectric sensors with DuraBeam laser technology

Miniature photoelectric sensors with DuraBeam laser technology.

Because no two applicatons are alike, R2, R3, R2F, and R3F series miniature photoelectric sensors offer you a large selection of different sensors. Choose the ideal sensor solution for your specific application based on four housing designs, three sensing modes, and two technologies―including the innovative DuraBeam laser technology. Read about the special features of DuraBeam and how you can use this technology to boost efficiency.

DuraBeam—the best of two worlds

Conventional laser sensors are extremely precise, but have a shorter durability and a lower temperature range compared to LED sensors. The new DuraBeam technology combines for the first time the advantages of LED sensors and laser sensors and makes them available in smallest housing design.

The powerful technology impresses with an extended service life and provides the user with new possibilities at elevated ambient temperatures of up to 60° C. DuraBeam also uses a special beam profile that differs from conventional photoelectric sensors. With its sharply contoured, circular light spot, sensors precisely detect even the smallest objects independently of sensor alignment.

More efficient applications

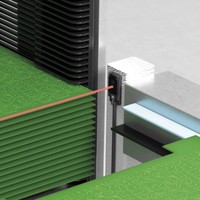

The DuraBeam laser technology is available across the entire R2 and R3 portfolio of miniature photoelectric sensors―even in the flat R2F and R3F models. Using these laser sensors, you can solve various application scenarios in a flexible, economical, and highly efficient way.

DuraBeam laser sensors increase throughput and maximizemachine efficiency.

This application shows the assembly of PCBs, in which the smallest electronic components are installed. Here, the manufacturing process requires sensors that reliably and precisely detect each of these tiny components. Conventional LED sensors require a significant amount of space between every piece. With their small light spot and quick response time, DuraBeam sensors need far less space between the components. This allows you to pack items closely together, which means that objects can be detected quickly and efficiently.

Highlights of miniature photoelectric sensors with DuraBeam technology

- Longer service life

- Maximum precision for detecting the smallest objects

- Higher operating temperature range up to 60° C

- Extremely small housing design for efficient engineering even in confined spaces of less than 200 mm

+1 330 425-3555

+1 330 425-3555