Achieving Industry 4.0 with Tablets for Hazardous Areas

Tab-Ex® 02 DZ2 Enables Digitalization and Traceability

The Application

The large ICAP-SIRA production site in Barberino di Mugello, Italy, specializes in the production, formulation, development, and marketing of specialty chemicals for the textile and non-wovens, coatings, and self-adhesive industries. The 118,000 m2 plant is one of the most modern in Europe, is highly automated, and meets the strictest safety standards and compliance with environmental regulations. In a large production site like Barberino, traceability and optimal management of all processes are crucial to optimize production times and meet safety regulations.

The Goal

The production site needed a system that allows complete traceability of finished products, their components and production processes, optimal management of storage and retrieval of orders, as well as optimization of production times, above all to avoid non-conformities. Over the years, the company transitioned from paper to scanning and archiving in digital format, but the system was still too burdensome and prone to errors. Additionally, the site was found to have a highly personalized management system, which made it challenging to find a compatible solution on the market.

The Solution

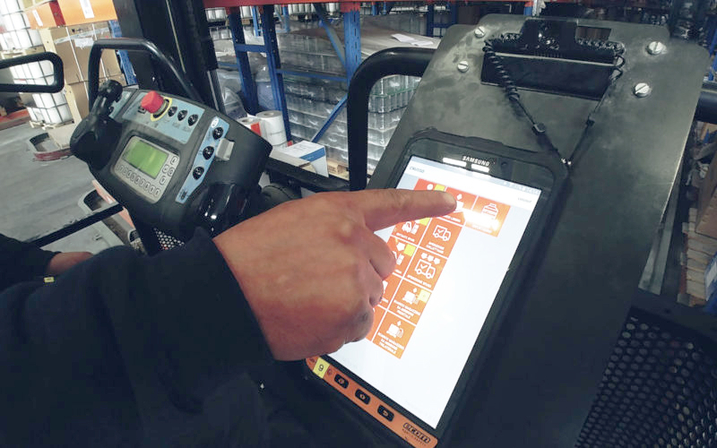

ICAP-SIRA discovered Mobiix, a mobile business solutions company that offers an extensive range of mobile enterprise solutions focused on evolving business processes into the digital age. Mobiix developed a customized project in which each operator was equipped with a Tab-Ex® 02 DZ2, the robust hazardous area-rated tablet from the Pepperl+Fuchs brand ECOM Instruments, to ensure complete traceability of each production phase, right up to the packaging of the finished product and its shipping, in addition to the availability of real-time data and an easily accessible and searchable historical archive.

The Benefits

The advantages are manifold: drastic reduction of all possible errors in production, complete traceability of the finished products, their components and production processes, and optimization of production times. All processes are now fully digitalized and stored so that they can be analyzed and aggregated for statistical purposes. Moreover, awareness in the security sector has increased significantly. By using tablets, GHS symbols and associated hazard warnings are now more visible, requiring the operator to check and confirm each step. With a simple click, the operator can access an excerpt from the safety datasheet of the raw material used. In addition, employee satisfaction is another factor that confirms the choice.

At a Glance

- Drastic reduction of all possible errors in production

- Complete traceability of the finished products, their components, and production processes

- Optimized production times and compliance with safety protocols

About ICAP-SIRA

Founded in 1945, the family company ICAP-SIRA Chemicals and Polymers SpA is specialized in the production of acrylic and urethane polymers in aqueous and solvent dispersion. With four diversified and highly automated production sites as well as an advanced and innovative research and development department, ICAP-SIRA operates on the global market with a range of excellent products and an integrated and efficient service. With a production capacity of 10 to 10,000 tons per year for each individual product, ICAP-SIRA is a production partner of leading multinational chemical companies.

+90 216 577 2250

+90 216 577 2250