Ultrasonic Sensors Knowledge (Part 4): Influences on Measurement Accuracy

Absolute accuracies of 1% to 3% are realistic in industrial applications for ultrasonic sensors in the operating range of -25°C to +70°C

With ultrasonic sensors, measurement accuracy usually refers to the absolute accuracy of the measured value at the analog output. Based on the echo transit time, the measurement accuracy of an ultrasonic sensor depends on several physical parameters. These parameters relate to the air as well as to internal tolerances.

Environmental influences

Air temperature

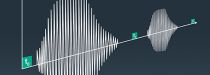

Air temperature has the greatest impact on the measuring accuracy of an ultrasonic sensor. After the transit time of the reflected ultrasonic pulse has been measured, the sensor calculates the distance to the object using the speed of the sound. However, as the air temperature changes, the speed of sound changes by 0.17% per degree Kelvin. Almost all Pepperl+Fuchs ultrasonic sensors have a temperature probe to compensate for this effect. This probe measures the ambient temperature and the sensor corrects the temperature-related distortion of the measured values (see temperature compensation).

Humidity

Humidity has negligible influence on the speed of sound at room temperature and at lower temperatures. However, at higher air temperatures, the speed of sound increases as humidity increases.

Air pressure

The speed of sound decreases by less than 1% between sea level and 3,000 m altitude. Atmospheric fluctuations at a specific location are negligible and the effects on the speed of sound are hardly measurable.

Air currents

If the object has the reflective properties of the standard reflector, regular air currents (wind) have no effect on ultrasonic measurement to speeds of 7 Bft (50-61.5 km/h). Stormy weather or hurricanes can cause unstable measurements (with loss of signal). Regarding changes to the speed of sound, no general conclusions can be drawn. This is because air current direction and air current speeds constantly change. For example, particularly hot objects, such as red-hot metal, cause significant air turbulence. The ultrasound can be scattered or deflected in such a way that no evaluable echo is returned.

Paint mist

Paint mist has no detectable effect on the operation of ultrasonic sensors. However, the mist should not be allowed to settle on the active transducer surface to avoid compromising the transducer’s sensitivity.

External noise

External noise is distinguished from the desired target echoes and generally does not cause malfunctions. If the source of disturbance has the same frequency as the ultrasonic sensor, the level of the external noise must not exceed the level of the target echoes. This can occur when filling a silo with stone, as an example.

Types of gas

Ultrasonic sensors by Pepperl+Fuchs are designed for operation in atmospheric air. Operation in other gases (for example in carbon dioxide) can cause serious errors of measurement or even total loss of function due to deviations in the speed of sound and attenuation.

Temperature compensation

Ultrasonic sensors operate using the echo transit time method, which means the time that is elapsed between the emitted ultrasonic pulse and when the received echo is evaluated. The ultrasonic sensor calculates the distance of the object from the speed of sound. When sound is propagated in air, the speed of sound is about 344 m/s at room temperature. However, the speed of sound is temperature-dependent and changes by approximately 0.17% with each degree Celsius. These changes affect the transit time and can distort the calculated distance. Most ultrasonic sensors by Pepperl+Fuchs have a working range of -25° C to +70° C.

Without temperature compensation and at a measuring distance of 100 cm, a 20° C change in temperature would cause a measurement error of -8.5 cm at 70° C and +7.65 cm at -25° C.

Therefore, most of these ultrasonic sensors are equipped with temperature probes whose measurements are used to correct the measured distances. This compensation is performed over the entire working range of the ultrasonic sensors from -25° C to +70° C and allows measurement accuracies of approximately ±1.5% to be achieved.

Accuracy

Accuracy/absolute accuracy refers to the difference between the output value that is measured by the ultrasonic sensor and the actual target distance. From a practical viewpoint, absolute accuracies of 1% to 3% are realistic in industrial applications for ultrasonic sensors in the operating range of -25° C to +70° C. Higher accuracies can be achieved in very stable ambient conditions. In this case, it is advisable to turn off temperature compensation (using the programming tool).

Another possibility would be to use an ultrasonic reference sensor. This approach involves mounting a second sensor of the same type parallel to the measuring sensor and aligning it to a fixed object. If ambient conditions in the measuring range change, the distance to the object will also appear to change due to the altered speed of sound. The measuring value must then be corrected by the value of this error.

PDF Downloads: Technology Guides Ultrasonic Sensors

Pepperl+Fuchs offers you various downloadable documents containing knowledge on ultrasonic sensors. In addition to a general technology guide on ultrasonic sensors, you can now download a new guide focusing on double material detection with ultrasonic sensors. Get your free PDF documents and benefit from valuable insights and advice for your field work!

- Ultrasonic Sensors Knowledge (Part 1): Technology and Functionality in a Nutshell

- Ultrasonic Sensors Knowledge (Part 2): Influences on the Sound Beam

- Ultrasonic Sensors Knowledge (Part 3): Different Operating Modes

- Ultrasonic Sensors Knowledge (Part 4): Influences on Measurement Accuracy

- Ultrasonic Sensors Knowledge (Part 5): Simple Installation and Assembly

- Ultrasonic Sensors Knowledge (Part 6): Synchronizing Ultrasonic Sensors

+358 20 7861 290

+358 20 7861 290