Ultrasonic Sensors Knowledge (Part 5): Simple Installation and Assembly

Cleaning the ultrasonic sensor

In this application, an ultrasonic sensor is used to detect printed circuit boards. What should you take into account when installing and assembling ultrasonic sensors?

Ultrasonic sensors can be installed and operated in any position, and they are largely immune to environmental conditions. However, there are a few things to keep in mind when setting up the ultrasonic sensors, in order to achieve ideal measurement results. For instance, when cleaning the ultrasonic sensor, ensure that the sensor surface (decoupling layer) and the integrated foam around the transducer are not damaged. Water droplets or crusting on the decoupling layer may impair the function of the ultrasonic sensor. Note: light dust deposits are not critical.

Direction of actuation

Object surface properties

Ultrasonic sensors can detect solids, liquids, and powders. The surface properties of the object are critical for the sensor’s echo evaluation. Level, smooth surfaces at right angles to the beam produce ideal reflections. The angular deviation of the measurement plate must not exceed 3° to ensure reliable detection.

Material properties such as transparency, color, or surface treatment (polished or matte) have no effect on detection reliability. Rough surfaces reflect the acoustic energy in multiple directions. This decreases the overall detection range. Conversely, rough surfaces allow greater angular deviation due to the predominantly diffuse reflection of the ultrasound signal.

This characteristic can be used to detect filling levels or piles of coarse-grained materials with an angular deviation of up to 45° (at a reduced range).

The following objects can be detected particularly well:

- All smooth and solid objects aligned perpendicular to the beam angle

- All solid objects with a surface roughness that cause diffuse reflections and that are randomly aligned

- Surfaces of liquids at an angle <3° from the beam axis

The following materials are poorly detected:

- Materials that absorb ultrasonic signals, such as felt, cotton, rough textiles, or foam

- Materials with temperatures of more than 100° C

In these cases, a thru-beam sensor may be required for such materials.

Sound beam and clearance

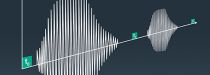

The response curve of ultrasonic sensors is referred to as a sound beam. Objects are detected within the sound beam if they reflect sufficient sound back to the ultrasonic sensor. The response curve depends on the reflective properties of the object. Therefore, sound beam diagrams are provided for various standard objects in the data sheets. The sound beam has no precisely defined limits and can change due to environmental influences such as temperature or humidity.

If unwanted acoustically reflective objects are present in an application, there must be clearance around the sound beam. This is the only way to avoid incorrect switching caused by unintended reflections.

Response curve 2 (25 mm round bar) can be used for orientation in the case of small, round, or poorly reflective objects. It can also be used for smooth surfaces that are mounted parallel to the ultrasonic sensor’s beam direction (container inner wall, pipes). Clearance corresponding to at least response curve 1 (flat panel 100 mm x 100 mm) must be provided for larger objects with good reflection properties (interfering edges).

If clearances cannot be maintained, many Pepperl+Fuchs ultrasonic sensors provide the option of modifying the sound beam. This procedure can be performed by using Teach-in buttons or with a programming interface and software. The software can be used to selectively suppress many interfering objects within the detection range (fixed-target suppression).

Minimum intervals for parallel mounting of ultrasonic sensors

Minimum intervals for opposite mounting of ultrasonic sensors

PDF Downloads: Technology Guides Ultrasonic Sensors

Pepperl+Fuchs offers you various downloadable documents containing knowledge on ultrasonic sensors. In addition to a general technology guide on ultrasonic sensors, you can now download a new guide focusing on double material detection with ultrasonic sensors. Get your free PDF documents and benefit from valuable insights and advice for your field work!

- Ultrasonic Sensors Knowledge (Part 1): Technology and Functionality in a Nutshell

- Ultrasonic Sensors Knowledge (Part 2): Influences on the Sound Beam

- Ultrasonic Sensors Knowledge (Part 3): Different Operating Modes

- Ultrasonic Sensors Knowledge (Part 4): Influences on Measurement Accuracy

- Ultrasonic Sensors Knowledge (Part 5): Simple Installation and Assembly

- Ultrasonic Sensors Knowledge (Part 6): Synchronizing Ultrasonic Sensors

+358 20 7861 290

+358 20 7861 290