Sensors from Pepperl+Fuchs for SIMOVE

Three sensor systems from Pepperl+Fuchs are now also compatible with SIMOVE. The AGV system platform from Siemens enables the simple integration of automated guided vehicle systems into a production environment. The sensors perform key tasks in the navigation and positioning of the mobile units.

SIMOVE from Siemens

In production and warehouse logistics, automated guided vehicles (AGVs) are taking over more and more transportation tasks. They are often referred to as AGVs or simply as bots. They pick up goods, transport, and transfer them automatically and move between different stations. Maximum precision is required for navigation with and without lane guidance. This is ensured not least by the R2000, PGV, and safePGV sensor systems from Pepperl+Fuchs, which are listed as compatible hardware for SIMOVE.

SIMOVE is a standardized system platform from Siemens with a modular structure and open interfaces. It offers great flexibility in the implementation of scalable AGV solutions and enables simple integration into existing infrastructures. SIMOVE comprises automation and drive components as well as suitable software tools and libraries. The vehicle fleet can be optimally configured with minimal technical and commissioning effort. With the integration of sensors from Pepperl+Fuchs, the possibilities for using the system platform are extended by proven and innovative technologies.

R2000 for Free Navigation

R2000 2-D LiDAR sensor

The R2000 2-D LiDAR sensor uses powerful Pulse Ranging Technology (PRT) for reflector and contour navigation. It provides a seamless 360° all-round view and delivers clear measurement results for determining the absolute position at all times. With a scan rate of 3000 revolutions per minute, it transmits 250,000 distance measurement values including the angular position. At 0.014°, it achieves the highest resolution on the market.

The range of the laser scanner can be adapted to the requirements of the respective vehicle class. It can be up to 60 m for natural surfaces and up to 200 m when using reflectors. A precise timestamp and a measurement data filter enable easy adaptation to the vehicle control system. The compact design allows easy integration even in small vehicles.

R2000 2-D LiDAR sensor ensures precise orientation for AGVs

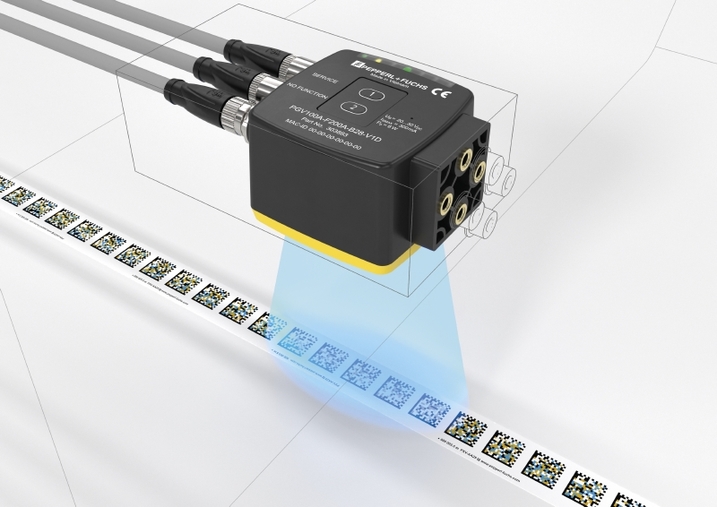

Guided Navigation with PGV

PGV and safePGV positioning systems from Pepperl+Fuchs

The PGV system from Pepperl+Fuchs uses color tapes attached to the floor for tracking as well as Data Matrix code tapes and tags for exact positioning. The read head consists of a camera module and an integrated high-performance LED lighting unit for reliable detection even in ambient light and on highly reflective surfaces. One Data Matrix code is sufficient to determine the position on the x-axis. In addition, the read head continuously outputs the position (angle, x, y) and speed.

The data from the ground-based navigation enables collision-free traffic when several AGVs are on the move at the same time. For real-time monitoring, the sensor emits a synchronization pulse and provides the image recordings with a timestamp. The vehicles can move simultaneously and at full speed, with a distance of only a few centimeters between them. The PGV*I*F200 product variant uses infrared lighting and can therefore also be used in areas where visible light may not be used.

Reliable navigation with the PGV read head and Data Matrix tags.

safePGV for Safe Absolute Positioning

The safePGV 2-D positioning system requires only one sensor in combination with multicolored Data Matrix codes for highly accurate and reliable position data. At 15 x 15 mm, the codes are larger than average and therefore easy to read. A single code is sufficient for precise positioning on the x-axis, but the camera always detects several codes simultaneously. Even if these are damaged over a distance of up to 75 mm, the position data is output with an accuracy of ±0.2 mm.

The red and blue LED rings of the lighting unit flash separately. The camera only recognizes one part of the colored codes per flash, which forms the basis for the system’s intrinsic redundancy. The sensor compares the signals with the expected value and determines whether the flash sequence matches the detected position. A safety controller and a safe algorithm ensure the independent plausibility check to prevent malfunctions. The safePGV is the only stand-alone device to achieve SIL 3 and PL e safety levels for the safe absolute positioning of bots and AGVs.

The safePGV from Pepperl+Fuchs enables safe absolute positioning according to SIL 3/PL e.

+90 216 577 2250

+90 216 577 2250