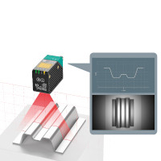

Based on the proven laser light section method, SmartRunner technology employs a laser line and a camera to precisely detect height profiles using the triangulation principle. The advantages of the laser light section method over typical vision sensors are especially clear in difficult ambient conditions. No external lighting is required, even with low-contrast objects such as metal on metal and single-color plastics. Even different surfaces, different colors, and extraneous light do not influence the measurement result.

SmartRunner technology offers the following innovative features

- Unique combination of height profile and 2-D image output in a single sensor

- Easy interpretation of line data due to output of 2-D images

- Simple diagnosis by analyzing error images

- Sensors optimized for specific applications for easy integration or raw data devices for maximum flexibility

- Reliable, precise detection via laser light section method—independent of surface condition and color

Typical Applications

- Presence check of small parts, e.g. rivets, screws and clamps

- Completeness check, e.g. of pens, tablets, etc

- Position check and output, e.g. of boxes, pallets and objects of any kind

Overview Laser Profile Sensors

The SmartRunner Explorer provides the innovative combination of height profile and 2-D image data in one sensor. This allows flexible implementation of many detection and surveying tasks. The Ethernet TCP/IP interface and available DLL offer a simple sensor integration into the programming environment.

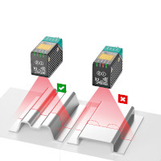

The SmartRunner Matcher is specially designed for comparing height profiles and provides simple solutions for presence, completeness, and position detection. The large detection field, the simple teach-in of the reference contour, and the intuitive operating wizard mean that the vision sensor can be quickly adapted to changing application requirements.

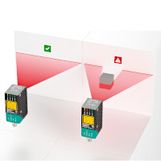

The SmartRunner Detector is specially optimized for high-precision area monitoring and detects even the smallest obstructions. The vision sensor enables users to protect sensitive machine parts and to design smooth process flows. Application-specific preconfiguration and factory calibration make integration and commissioning quick and easy.

Suitable accessories such as fieldbus gateways and mounting aids for the laser profile sensors simplify integration into the respective plant.

+47 3557 3800

+47 3557 3800