Operating Modes

Determining the distance to an object using the echo transit time method can be evaluated and displayed in different ways. Besides, the height of the echo amplitude can be used for evaluation purposes.

In general, a distinction can be made between four operating modes of ultrasonic sensors.

Diffuse mode sensors—all-in-one detection and measurement

In this type of sensor, the emitter and receiver are located in the same housing. This design simplifies installation and is well suited for fill level detection in tanks. The surface of the filling material reflects the emitted sound waves so that the sensor registers a limit level and continuously measures the level.

Features

- Easy to install, only one sensor head

- Foreground and background suppression possible (window mode)

- Object serves as a reflector, alignment is important

- Switching frequency is lower compared to a thru-beam sensor

Retroreflective sensors—sensor function thanks to a reflector

Not the object itself, but a background used as a reflector (such as a conveyor belt, machine part, or the floor) ensures a secure function of the retroreflective sensor. Regardless of whether they are small, big, angled, or sound-absorbing—all types of objects located between the sensor and the reference object are detected. Here too, the one-piece housing enables easy installation, wiring, and commissioning.

Features

- Easy to install, only one sensor head

- Reliably detects problematic objects (sound-absorbing, slanted surfaces)

- Reference object/background is used as a fixed reflector; the object disturbs/breaks the beam

- Switching frequency is lower compared to a thru-beam sensor

Thru-beam sensors—for large ranges and high switching frequencies

Thru-beam sensors operate with separate emitter and receiver transducers. If an object such as a bottle interrupts the sound beam, the sensor switching output is activated. Even sound-absorbing objects are securely detected. Another benefit of the thru-beam principle over the diffuse mode sensor is the doubled range. Additionally, the switching frequency of thru-beam sensors is considerably faster, paving the way for numerous fields of (high-speed) applications.

Features

- Two sensor heads must be installed and wired

- Long range, i.e., large distance between emitter and receiver possible

- Reliably detects problematic objects (sound-absorbing, slanted surfaces)

- Very high switching frequency, defined response characteristics

Double sheet sensors—reliable and safe object detection

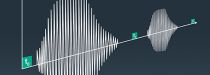

In addition to the previously described ultrasonic sensors, there are also double sheet sensors: instead of measuring transit times, they assess the amplitude attenuation the caused by the respective object (e.g., sheets of paper).

Features

- Very high processing speed

- Detection of sheet and roll materials on multilayer feeds or splices

- Label identification and counting

- Suitable for use on shiny and transparent materials

- Detection of plastic or metal films/sheets and particle boards

- Insensitive to dust and dirt

+55 11 4007 1448

+55 11 4007 1448