Ultrasonic Sensors for Anti-Collision Detection on Aerial Work Platforms

Indispensable on construction sites

Ultrasonic sensors of the Varikont L2 Series are ideal for installation on work platforms due to their compact design

Drivable aerial work platforms are common on many construction sites. These platforms facilitate working in high locations and increase productivity. However, since severe accidents involving aerial work platforms may occur due to collisions, the safety aspect should not be ignored.

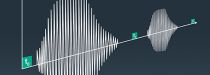

Ultrasonic sensors effectively safeguard the operation of this equipment. Using ultrasonic sensors, you can monitor the area below the work platform, underneath the arms, and around the vehicle. Collisions between the machine and obstacles such as trees, buildings, or persons can be prevented.

If the ultrasonic sensors detect an object in close proximity, the machine switches to slow speed. In the case of acute danger of collision, machine movement stops completely.

Working safely with aerial work platforms

To safeguard the equipment, ultrasonic sensors are attached to the appropriate points on the aerial work platform. In order to prevent mutual interference of the sensors and simultaneously ensure the shortest possible response time, these sensors must be common-mode synchronized. As aerial work platforms are mainly used in outdoor applications, the sensors must be suitable for such an environment.

Monitoring the area below and around the machine ensures that collisions with other machines, buildings, or objects does not occur. Damage is prevented and machine availability is increased.

To safeguard the equipment, ultrasonic sensors are attached to the appropriate points on the aerial work platform

Your benefits at a glance

- Continuous monitoring of aerial work platforms

- Increased safety for personnel and machine

- Prevention of damage to objects

- Increases in productivity

PDF ダウンロード: 超音波センサ テクノロジー・ガイド

Pepperl+Fuchsは超音波センサに関する知識などの様々なドキュメントを提供します。超音波センサの一般的な技術ガイドに加えて、超音波センサによる重送検知を紹介した新しいガイドをダウンロードできます。PDFドキュメントは無償でダウンロードできます。

+81 45 6249077

+81 45 6249077