RFID System for Exact Filling of Reservoir Trucks

Long Range F192 UHF Read/Write Device Ensures Efficient Water Supply Management

The Application

In mining, sprinkler systems are often operated with reservoir trucks. At strategic points in the mine, these trucks are supplied with water via a mechanical construction with a pipe, the so-called filling system. The water supply is often performed manually and without control of the capacity or traceability of the truck. As soon as the reservoir truck has passed the supplier, it travels a distance through the mine and pours out water. This keeps the dust in suspension and thus also complies with the standards enforced by environmental protection agencies.

The Goal

The aim is to supply the water storage tank with the amount of water that corresponds to its capacity in liters. The key problem to be solved is the waste of water and the lack of control over water consumption. Due to the challenging environmental conditions, the equipment used must be resistant to the aforementioned iron ore dust, sun and water, as well as other contaminants and harsh weather conditions in mining.

The Solution

As soon as the presence of a water truck has been detected by the ultrasonic sensor UB*-30GM, the ideal product for reliably identifying the truck is the RFID read/write device F192. The sensor reads the information from the UHF tag attached to the vehicle’s tank. Then, the evaluation unit sends this information to the controller, which in turn relays the data to the supplier’s flow transmitter—guaranteeing the exact water flow for a supply according to the capacity of the truck. With its extended read range of up to six meters and significant features such as switchable antenna polarization for reliable tag identification, the sensor allows maximum flexibility in relation to the position where the truck is parked. In addition, preassembled function blocks enable the RFID read/write device to be quickly and easily integrated into the application.

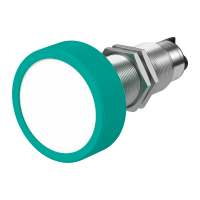

IUH-F192 RFID read/write device

Technical Features IUH-F192-V1-FR1*

- Sensing range: up to 6 m

- Operating frequency: 865 … 928 MHz

- Ready-made PLC function blocks

- Robust housing

- Degree of protection: IP67

- Temperature range: –20 °C … +70 °C

- Switchable antenna polarization

- Multitag reading

- For connection to IDENTControl evaluation unit

Technical Features IUC87-F257-T17-M-FR*

- Operating frequency: 865 … 928 MHz

- Complies with EPC Gen2 (ISO/IEC 18000-63)

- Optimized for mounting on metal

- Sturdy housing, suitable for rough industrial use

UB*-30GM ultrasonic sensor

Technical Features UB*-30GM

- Sensing range: up to 6,000 mm

- Operating voltage: 10 … 30 V DC

- Degree of protection: IP65

- Synchronization function

- Robust housing

The Benefits

The IUH-F192 RFID read/write device has a high degree of protection (IP67) and an extended temperature range, ensuring maximum process reliability in challenging environmental conditions. As the UHF antenna is mounted inside the housing, the need for error-prone extra components such as coaxial cables is eliminated. If required, the sensor is able to detect several RFID tags simultaneously with just a single read operation (multitag reading).

The long-distance IUC87-F257-T17-M-FR* UHF tag can be attached directly to the truck’s metal tank. The tag is cost-effective and has the capacity to store additional information about the truck such as tank capacity, real-time status, and location. In addition, the RFIDControl software can be used to retrieve the status of the IUH-F192 RFID read/write device and the tag response.

At a Glance

- UHF RFID read/write device for long ranges reliably identifies water trucks

- Forwarding of data via the RFID evaluation unit and controller to the flow transmitter

- Long-distance UHF tag can be attached directly to the truck’s metal tank

+81 45 6249077

+81 45 6249077