集光型太陽光発電、集光型太陽光蓄電

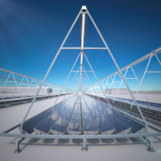

The surface temperature of the sun is about 5,800 °C. Only a fraction of this reaches the earth, but still enough to convert this thermal energy into electrical energy. Mirror collectors in solar thermal power plants bundle the solar heat and reflect it onto an absorber. The resulting extremely high temperatures drive turbines with generators. In this way, climate-neutral electricity is generated from solar heat.

Whether in parabolic trough power plants, Fresnel systems or solar power towers: Powerful sensor technology is required to align the mirrors to the position of the sun and ensure efficient utilization of the solar heat. For this purpose, rotary encoders and inclination sensors from Pepperl+Fuchs are used. Inductive sensors for end position feedback are also frequently found in solar thermal power plants.

Because these power plants make use of the sun's heat, they are particularly suitable for deserts and desert-like landscapes with high solar radiation. These areas are characterized by extreme temperature differences between day and night, as well as by sandstorms or other deposits in the air. For these demanding environmental conditions, Pepperl+Fuchs offers sensors with high temperature resistance, tightness, and freedom from wear.

Fresnel systems consist of a large number of mirrors—also called heliostats—that reflect the sun's heat onto an absorber. A heat transfer medium inside the absorber is heated by solar radiation, driving a steam or gas turbine to generate electricity. To avoid stray losses due to inaccurate alignment, inclination sensors detect the horizontal orientation of the heliostats. With its robust housing and extended temperature range, the F99 inclination sensor from Pepperl+Fuchs is ideal for this application. The sensor not only withstands extreme temperatures, but also impresses with a highly precise measurement so that the mirrors can be optimally aligned with the sun.

In solar power towers, a large number of movable mirrors reflect sunlight onto a specific field in a solar tower. Both horizontal and vertical tracking is necessary so that the mirrors can follow the position of the sun. For horizontal tracking, the MNI40 magnetic incremental rotary encoder is used: it has no mechanical wear parts and is suitable for extreme environmental conditions. The same applies to the F99 inclination sensor, which is responsible for the vertical alignment of the heliostats. Not only the immunity to environmental influences, but also the high precision of the sensor technology from Pepperl+Fuchs is essential in this application: the mirrors must be calibrated with maximum precision so that the temperatures in the solar tower do not become too high.

+81 45 6249077

+81 45 6249077