インクリメンタルロータリエンコーダは、シャフトの回転ごとに特定数のパルスを出力します。一定時間帯のパルスを数えることによって速度の測定も可能です。角度または距離を計算するためには、基準点を設定しその点からのパルス数を計数する必要があります。

2相、矩形波出力エンコーダは、90度の位相差を持つ2つの出力信号を特長としています。これによってコントローラが回転の方向を判断し、双方向の位置決めを行うことができます。

その上、3チャンネルインクリメンタルエンコーダは、1回転ごとに1パルスを出力する3番目の信号チャンネル((「ゼロ」、基準、信号として知られています)があります。

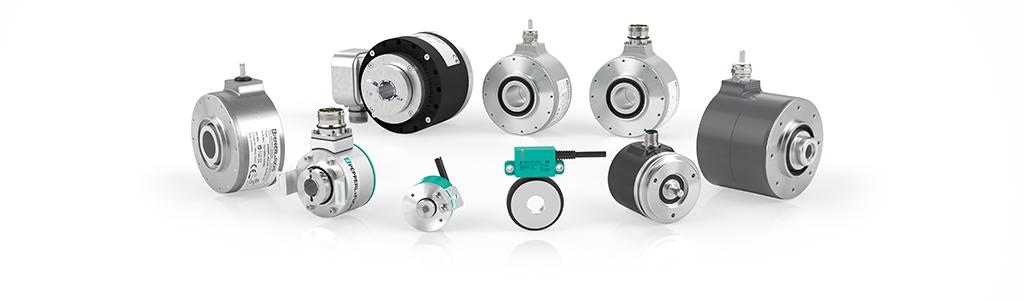

Heavy-Duty Incremental Rotary Encoders

The heavy-duty incremental rotary encoders from Pepperl+Fuchs are designed to work reliably in harsh conditions—for example, in outdoor process plants or in construction machinery in dusty, dirty environments. Due to their robust design, the heavy-duty rotary encoders easily withstand heat, cold, dirt, constant vibrations, strong shocks or electromagnetic interference. As a result, they deliver precise measurement results at all times. This makes them the ideal solution, e.g., for speed feedback in large asynchronous motors.

Offshore Incremental Rotary Encoders

Whether in wind turbines near the coast or on the high seas—the offshore incremental rotary encoders from Pepperl+Fuchs were specifically developed for use in maritime applications and in particularly cold regions. With a temperature range of -40 °C to +60 °C, the offshore rotary encoders withstand strong temperature fluctuations. Their seawater-resistant housing protects them from corrosion. At the same time, the robust sensor design with special housing coating guarantees a long service life. In this way, the offshore rotary encoders ensure high availability of wind turbines, gantry cranes or spreaders, which are often difficult to access and therefore require a high level of maintenance.

Incremental Rotary Encoders for Hazardous Areas

Sensor technology that is used in hazardous areas needs to fulfill special requirements. The incremental rotary encoders for these areas are therefore available with EU-type examination certificates up to Zone 1, including flameproof enclosure (Ex d) and intrinsically safe (Ex i) types of protection. Their robust housing design increases service life and reduces maintenance work. Whether in the chemical industry, in wastewater treatment plants or in power plants: Wherever explosive atmospheres can form, incremental rotary encoders from Pepperl+Fuchs ensure safe process operations.

Safety Incremental Rotary Encoders

For machines that require safe functionality in accordance with the Machinery Directive 2006/42/EC, Pepperl+Fuchs offers incremental rotary encoders with certification up to SIL 3/PL e. They are, for example, used in machine tools, overhead conveyors or packaging machines. Here, the sensors monitor motion sequences, ensure safe speeds in the event of malfunctions, and throttle speeds down to a standstill. In this way, the safety rotary encoders prevent hazards for the operating personnel as well as damage to the machines.

Incremental Rotary Encoders for Food Applications

Particularly high hygiene requirements are placed on sensors used in the pharmaceutical, chemical or food industries. For this reason, Pepperl+Fuchs has developed an incremental rotary encoder with a hygienic design: The sensor's stainless steel housing is designed to meet hygiene requirements and ensure microbiological safety in accordance with EHEDG. In addition, the rotary encoder is insensitive to aggressive chemical cleaning agents and disinfectants. Due to its resistance to thermal shock, it can be easily cleaned with high-pressure equipment. These features shorten cleaning times and therefore increase machine availability.

+81 45 6249077

+81 45 6249077