Applications for Ultrasonic Sensors

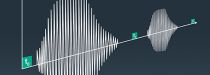

Ultrasonic sensors detect objects within the sound beam. In the packaging industry, different sound beam widths can be set up in order to determine roll diameter and detect web breaks.

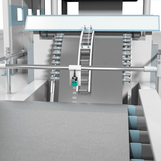

Mobile hydraulic lifts are monitored with multiple ultrasonic sensors mounted closely together. In order to prevent them from influencing each other, two different types of synchronization are used, depending on the application.

For specially regulated industries such as pharmaceutical and food industries, Pepperl+Fuchs offers certified solutions.

Ultrasonic sensors are extremely reliable even under harsh environmental conditions. This is especially beneficial when sensors are used in outdoor areas like gravel plants, silos, barrier systems, or mobile vehicles.

Especially rugged sensor solutions are designed for outdoor applications. They are used on the booms of field sprayers on agricultural vehicles, where they convey important information about height control.

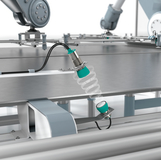

Ultrasonic sensors’ insensitivity to countless materials, surface textures, and colors is ideal for packaging industry applications, where materials such as transparent film, colored paper, and shiny labels are used. Ultrasonic sensors provide reliable detection of material sagging and ensure continuous material supply.

A multilayer feed of materials such as paper, cardboards, sheets, foils, or labels can lead to machine downtime, process disruptions, and waste. Double sheet sensors prevent defective material feeding und ensure safe processes and high plant availability.

+82 2 34819494

+82 2 34819494