Ultrasound—but Different: USi®-industry Ultrasonic Sensor System

The new USi-industry ultrasonic sensor system enables reliable three-dimensional area monitoring

Pepperl+Fuchs is adding the powerful USi-industry ultrasonic sensor system to its wide portfolio of ultrasonic sensors. Its compact design, decoupled ultrasonic transducers, and elliptical sonic lobe make it significantly different from standard ultrasonic sensors and offers exceptionally high flexibility in applications and ruggedness. Independent sensor channels, switchable parameter sets, and various operating modes allow easy adaptation to different applications, while the sensor system’s robust design ensures reliable three-dimensional area monitoring both indoors and outdoors—demanding conditions included.

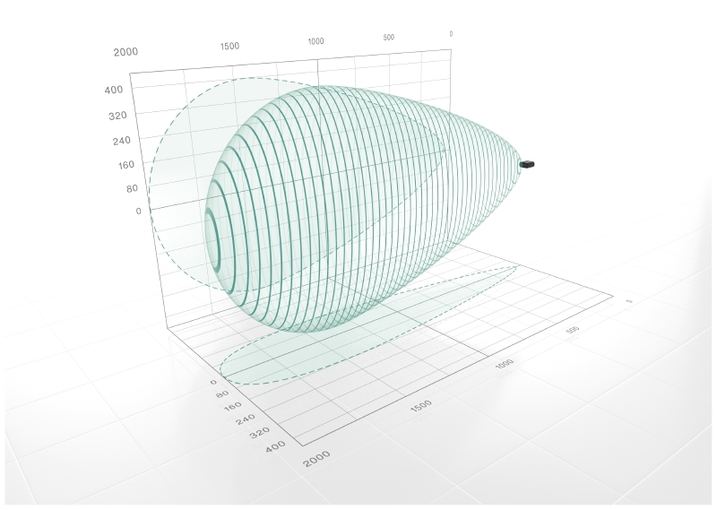

Wide Sensing Range Due to Elliptical Sonic Lobe

This three-dimensional area monitoring is made possible by the unique sonic lobe shape of the USi-industry: with conventional ultrasonic sensors, the sound waves spread out in a cone-shape, while the cross section of the sensing range is round. By contrast, the sonic lobe of the USi system has an elliptical cross section. This characteristic offers a major advantage in object detection in an extended monitoring range. For example, with load detection, objects of different contours such as pallets, crates, frames etc. can be reliably detected.

Decoupling and Wide Sensing Range Create Flexibility

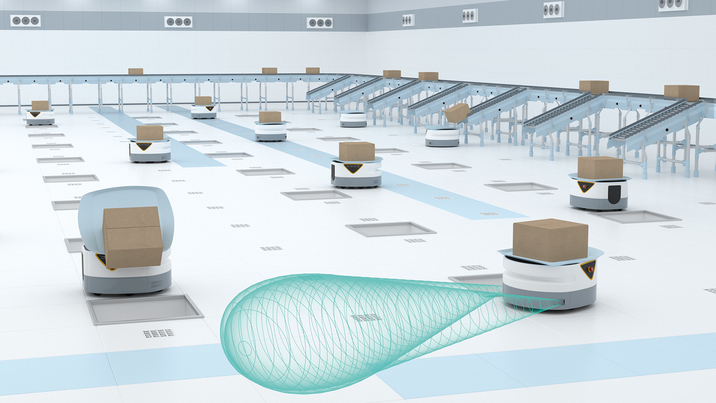

The dimensions of the two ultrasonic transducers—the actual sensing units of the system—are only 27 x 21 x 13 mm. They are decoupled from the evaluation unit and can be mounted up to three meters cable length away from it at various points. Along with the compact design, this concept allows significant flexibility in the placement of the individual components. For example, the compact transducers can be mounted directly onto a robot arm or in an autonomous mobile robot (AMR) to ensure targeted speed and distance monitoring as well as reliable collision protection.

Intelligent Software, Switchable Parameter Sets

The evaluation unit has an intelligent software algorithm for processing the sound signals. If several USi systems are used in the same environment, this automatically hides the interference echo that may arise and enables parallel use in the event of encounters. The evaluation unit allows the connection of up to two ultrasonic transducers with their own channels, which can be individually configured via PACTware. Two parameter sets are available for each transducer for distance, evaluation, outputs, and teach-in, which can be switched via a parameterizable digital input in the application. Because one evaluation unit is sufficient for two sensors, investment costs remain low.

Selective Evaluation in Three Operating Modes

The USi-industry learns how to detect its environment in detail in teach-in mode. During teach-in, a reference point can also be defined to rule out tampering of the sensor detection. This can be a stationary machine part in the sensing range, for example. The users can select what the sensor should react to: present or absent objects, or both types of object change. The selective evaluation is set after the environment has been taught in and therefore adapted to the requirements of the application.

This also applies to the sensor cycle time, which can be set in a range between 10 and 200 milliseconds. A short cycle is used to detect objects moving quickly; longer distances stabilize the measurement in high-impedance environments. The ultrasonic transducer of the USi-industry complies with IP69 degree of protection, is resistant to moisture, and can also be used in exposed areas without any problems.

Typical Applications

USi-industry sensors are often used in automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), for example in production areas or in warehouses and shipping centers. Other areas of use include robotics applications and aviation, for example for collision protection between aircraft and baggage conveyor vehicles.

Highlights of the USi-industry Ultrasonic Sensor System

- Detached sensor system provides installation flexibility—the miniature ultrasonic transducers fit in tight spaces

- Optimal area monitoring through unique elliptical 3-D detection field

- Maximum flexibility due to independent channels, each with two switchable parameter sets

- Three selectable operating modes and adjustable sensor cycle time for optimum adaptation to the application

- Easy sensor integration and high tamper protection due to simple teach-in of the environment

- Maximum reliability: mutual interference echo suppression ensures smooth operation

+32 3 644 25 00

+32 3 644 25 00